Safety software Unified Operations Center for Miningmonitoringengineeringtracking

Add to favorites

Compare this product

Characteristics

- Function

- monitoring, engineering, safety, tracking

- Applications

- process

- Type

- real-time, centralized

Description

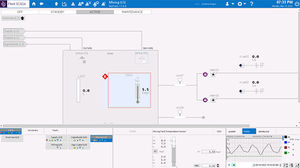

Increase visibility from pit to port. Track equipment geographically, monitor asset health to prevent downtime, and optimize operations through a single view.

Make agile decisions across the entire mining value chain with the centralized view from AVEVA Unified Operations Center for Mining. Better predict inventories and blends of raw materials to improve recoveries and reduce the impact of logistic disruptions. Uncover value by pairing broad insights with context from production events and follow your operations from pit to port. Use these insights to augment the capabilities of integrated remote operations centers for mining value chains.

Agility and resiliency through operational awareness

Improve agility and decision-making across the entire mining value chain with a centralized view from AVEVA Unified Operations Center for Mining. Using a system of systems approach, it converges operations technology (OT), information technology (IT), and engineering technology (ET). By giving you a single pane of glass through which to view contextualized information, you can:

Better predict inventories of raw materials blends

Optimize production processes and produce inventory positions

Identify operational deviations and production anomalies fast for quick recovery

Reduce logistical disruptions and minimize loss

Evaluate asset performance and equipment health

Increase visibility and better manage environmental, safety, and governance (ESG) standards

Follow your operations from pit to port

VIDEO

Catalogs

No catalogs are available for this product.

See all of AVEVA Group plc‘s catalogsRelated Searches

- Automation software solution

- Management software solution

- Analysis software solution

- Process software solution

- Windows software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Online software

- Design software solution

- 3D software solution

- Monitoring software solution

- Interface software

- Measurement software

- Industrial software solution

- Quality software

- Simulation software

- Visualization software solution

- Programming software

- Automated software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.