Identifies the weakest links in your production lines and restores them to run at their full operating potential.

Line Bottlenecks and Performance Visibility

Access in-depth analytics by drilling down using function and time slicing methods – zoom into the root cause of line constraints.

Real-time capturing and visibility of production equipment utilization, performance, and production progress (Can be viewed on the production line and web clients that link to the corporate network)

Capture extended period of data by categories, enabling decision making based on sufficient information.

Line Performance dashboard and reports are based on Lean Manufacturing and Total Productive Maintenance (TPM) practices. They offer critical information for the production, quality, and maintenance teams, such as OEE details, loss analysis, production details, Mean Time Between Failures(MTBF) and Mean Time To Repair (MTTR)

Leaner Production Processes

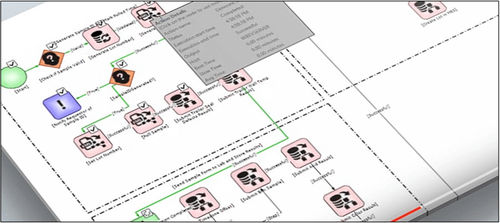

Process Configuration & Data Categorization - Once the process model is defined, work order, dashboard, and reports will follow the definition and bring meaningful information for performance evaluation.

Utilization Management - Out of the Box Interface to handle utilization event(s), The interface also supports commenting, merging and splitting of the event, enabling accurate reporting.

Model-Driven Approach - Allows for allows best practices and business rules to be brought into the system through workflow capability.

Work Order Management & Execution - The work order management console consists of a work order overview for the whole plant's production status monitoring.