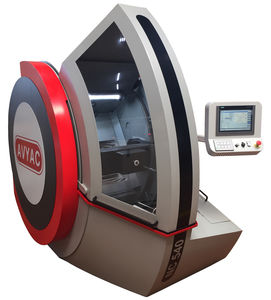

Drill bit sharpening machine NC 18automaticCNC5-axis

Add to favorites

Compare this product

Characteristics

- Applications

- drill bit

- Control type

- automatic, CNC

- Number of axes

- 5-axis

- Other characteristics

- compact, high-productivity, with touch screen

- Spindle speed

6,000 rpm

(37,699 rad.min-1)- Power

2.2 kW

(2.99 hp)

Description

Fully automated production and regrinding machine for carbide and HSS drills from Ø1 to 14.5 mm

Fast, simple, reliable, accurate, the ultimate cost saver

Choosing the NC18 for your workshop means giving yourself flexibility in the choice of production and sharpening of carbide and HSS drill bits.

A short training is enough to allow your operators to produce a wide variety of sharpening geometries, such as conical or facets relief, web thinning, second point angle, steps…

Compact size : machine dimension 1400 x 1200 x 1500 mm (4.6ft x 3.9ft x 5ft)

Kinematics : ideal 5 axis arrangement, short travel distances, time saver

Touchscreen, plug and play : AVYAC's software simple, visual, logical

Ergonomics : external charging, safe operation, simple, reliable

Fully automatic : economical circular loader with up to 90 tools, for serial ou differentiated programs

1. 5 axis NC : SIEMENS 840D SL with touch screen, allows a multitude of applications: twist drills, end mill up to 4 teeth, step drills, Gundrills, wood drills, countersinks, punches, engraving points...

Contact us for special tools

2. Clamping devices : with jaws or collets,

W12 Schaublin collets Ø1-8mm

W20 Schaublin collets Ø2-14.5mm

6 jaws mandrel Ø5-14mm

3. Loader : circular loader capacity 90 tools. Individual adjustment possible

4. Internal container : automatic, gentle unloading via pneumatic actuator in oil

Right-hand helix twist drills with conical or facets relief

Gundrill bits for deep holes drilling with 1 or 2 flutes

Metal sheet drills

Step drills

Flat Bottom Drill Bits

Brad point, woodworking drill

Reamer

End mills with 1, 2, 3 or 4 lips

Countersinks

Taps

Engraving tools

Punches…

VIDEO

Catalogs

NC18-Detailled doc-EN

29 Pages

NC 18

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.