- Products

- Catalogs

- News & Trends

- Exhibitions

Linear position sensor K1Gnon-contactCMOS laseranalog

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Contact / non-contact

- non-contact

- Technology

- CMOS laser

- Output signal

- analog, digital, EtherCAT, serial

- Measurement object

- transparent

- Applications

- industrial

- Other characteristics

- high-precision, high-speed

- Measuring range

Min.: 0 mm

(0 in)Max.: 15 mm

(0.59 in)

Description

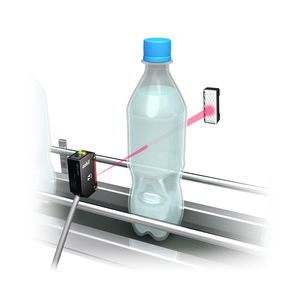

azbil’s new High-Performance Laser Sensor, the K1G series, far exceeds conventional norms when it comes to performance and functions, allowing you to make the measurements you want.

A combination of a CMOS linear image sensor and collimated lasers ensures high-accuracy workpiece position measurement.

Description

See what you previously couldn't

The K1G has the highest display resolution (0.1 µm) and fastest measurement cycle (250 µs) in its class. This enables the K1G to reliably detect and visualize tiny variations and high-speed fluctuations that are often overlooked by conventional sensors.

Up until now glass edges and surfaces were checked offline by operators for defects such as chips. The K1G series, however, makes high-speed in-line measurements with a high degree of accuracy. This means that fast, highly accurate glass measurements can now be made regardless of how the edge surface is processed.

Azbil’s unique FDN algorithm, which utilizes Fresnel diffraction phenomena and sophisticated high resolution technologies, has achieved detection accuracy to 1µm.

The detection principle also works well for transparent object detection. Azbil developed a special lens to achieve almost perfectly parallel optical light. Afterwards a CMOS linear sensor was added as the light-sensitive element to enable visual perception for workpiece position. These functions enable the K1G to detect small variations that conventional sensors are not able to detect.

VIDEO

Catalogs

High-Accuracy Position Sensors

16 Pages

Related Searches

- Azbil proximity sensor

- Cylindrical proximity switch

- Position transducer

- Inductive proximity switch

- Azbil photoelectric sensor

- IP67 proximity switch

- Linear position transducer

- Azbil limit switch

- Analog output position sensor

- Azbil rectangular photoelectric sensor

- Non-contact position transducer

- Threaded proximity switch

- Stainless steel proximity switch

- LED photoelectric sensor

- Industrial position sensor

- Rectangular proximity switch

- Azbil infrared photoelectric sensor

- Cylindrical photoelectric sensor

- Compact photoelectric sensor

- Waterproof photoelectric sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.