- Packing - Handling - Logistics

- Packing and Packaging

- Serialization machine for the pharmaceutical industry

- b+b Automations- und Steuerungstechnik GmbH

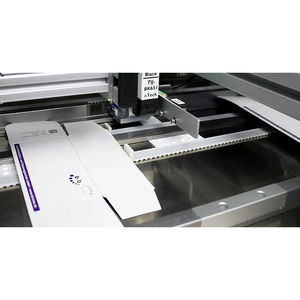

Serialization machine for the pharmaceutical industry MS-PV-AG-C

Add to favorites

Compare this product

Characteristics

- Applications

- for the pharmaceutical industry

Description

The workstation enables the manual serialisation of pharmaceutical packs and their aggregation into shipping cartons. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system and then manually placed in a shipping carton.

As soon as this is filled, the downstream thermal transfer printer creates an individual serialisation label. The correct print data and print quality are monitored by a camera system.

The operator places the drug packs to be labelled at a reference edge of the conveyor belt. As soon as the printer has printed the serialisation data, it is checked for correctness by the integrated image processing system. In case of an error, the product stops at a certain position, which is marked by red LEDs.

Depending on the number of products in the shipping carton/number of aggregation levels, approx. 10-12 products/min are serialised.

Catalogs

Other b+b Automations- und Steuerungstechnik GmbH products

Labelling of folding boxes

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.