- Products

- Catalogs

- News & Trends

- Exhibitions

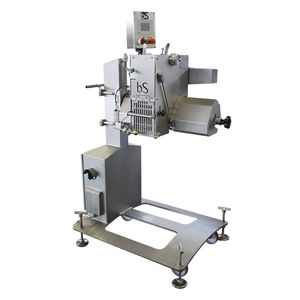

Automatic dispenser dap130

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

Description

The DAP130 automatic bread dispenser was created to carry out programmable distribution on a belt for the production of sandwiches, toasts or canapés.

The machine is composed of various stores, from a minimum of 8 to a maximum of 12, with autonomy of approximately 100 slices of bread each.

The slices are picked up by suction cups that work individually on each channel, that are in turn independently driven by a motor.

According to requirements, the machine can be arranged to work in parallel on one or two rows of bread.

Features

All functions are managed from a control panel and commanded by PLC in order to allow the machine greater flexibility in adapting to the various types of bread.

The format can be changed through operations that do not require the use of tools.

• Facilitated displacement

The structure is constructed entirely in stainless steel and mounted on swiveling wheels in order to facilitate movement during cleaning operations.

• Slices size

The DAP 130 can set down slices with dimensions that vary from min. 80 x 80 mm to max. 150 x 150 mm with a minimum thickness of 8 mm and a maximum of 15 mm.

• Protections

The machine is also equipped with protective devices for immediate stoppage during removal operations caused by incorrect or hazardous maneuvers.

Related Searches

- Volumetric dosing unit

- Liquids dosing unit

- Solid dispensing system

- Dosing unit for the food industry

- Automated dispenser

- Continuous dispensing system

- Hopper dosing unit

- Pneumatic dosing unit

- Screw dosing unit

- Piston metering system

- Semi-automatic dispensing system

- Pasty product dosing unit

- Single-component dispensing system

- Dosing dispenser with vibratory feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.