- Products

- Catalogs

- News & Trends

- Exhibitions

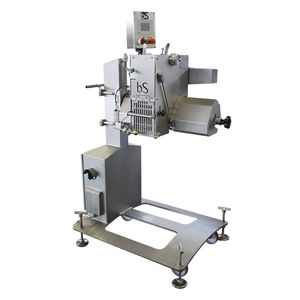

Wire cutting machine tbs65foodstufffor electrical wirePLC-controlled

Add to favorites

Compare this product

Characteristics

- Technology

- wire

- Material

- foodstuff

- Product handled

- for electrical wire

- Control type

- PLC-controlled

- Configuration

- cantilevered

Description

The one-row sandwich cutter is designed for diagonally cutting sandwiches after filling.

The structure of the machine is made with stainless steel tubes, arranged at 45°, continuously welded to obtain a better cleaning, and sides in anodized aluminum.

The whole is positioned on swivel wheels in order to facilitate movement for washing.

Adjustable feet are used to keep the machine in place. With electro-mechanical functions, just one, 380 V socket is needed for the cutter to work.

Maximum sandwich sizes that can be cut: 150 x 150 mm - thickness 60 mm, minimum size: 80 x 80 mm - thickness 20 mm.

Maximum machine output: 65 sandwiches a minute.

The cutter can be built right or left, according to the required needs.

To obtain faster cleaning and maintenance of the belts and belts, the rollers are all mounted cantilevered.

Features

All the stainless steel protections are also provided and those that can be opened are controlled with a safety microswitch in order to block any movement of the machine.

The machine works by 4 motors which have the following functions:

• Main motor

that drives the contrast inlet belts and straightening and unloading belts

• Motor

which activates the cutting blade with an alternating movement

• Two Motors

that arrange the sandwiches perfectly aligned at 45 ° before cutting

Specifications

All the machine functions are managed with a PLC to allow, through a panel, to adapt the cutter to the various formats and speeds.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.