- Products

- Catalogs

- News & Trends

- Exhibitions

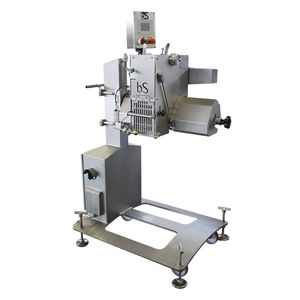

Liquids dosing dispenser db100for the food industrypneumaticcontinuous

Add to favorites

Compare this product

Characteristics

- Product

- liquids

- Applications

- for the food industry

- Other characteristics

- pneumatic, continuous, hopper

Description

The dispenser DB100 (for butter) has been designed and built with innovative and targeted methods.

The structures of the machines are made with stainless steel tubes, arranged at 45° and continuously welded, allowing better cleaning.

These dosers have the considerable advantage of being able to be anchored directly to the linear belt of our production, or to be mounted on swivel wheels that allow transport, allowing minimum encumbrance.

To achieve total precision, the dispensers have the ability to be adjusted in all directions. Another important feature is that the metered amount can be controlled via a panel; recipes can be stored and recalled for future applications.

Features

A photocell is fitted on the hopper to ensure continuous presence of the product in the dispenser.

The dispensers require 380 V voltage and air supply. The machines consist of the following parts:

• Product feeding hopper,

with level sensor for automatic call

• Product distribution nozzle

• Electrical control board

• Touch Screen controls

• Heating system

(used with products such as butter or similar)

Related Searches

- Volumetric dosing unit

- Liquids dosing unit

- Solid dispensing system

- Dosing unit for the food industry

- Automated dispenser

- Continuous dispensing system

- Hopper dosing unit

- Pneumatic dosing unit

- Screw dosing unit

- Piston metering system

- Semi-automatic dispensing system

- Pasty product dosing unit

- Single-component dispensing system

- Dosing dispenser with vibratory feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.