- Products

- Catalogs

- News & Trends

- Exhibitions

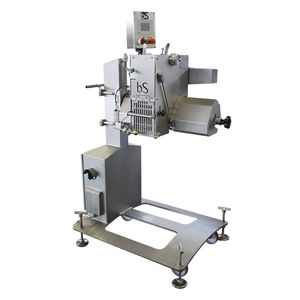

Belt conveyor inclinedtransportfood

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- inclined

- Function

- transport

- Transported product

- food

- Sector

- for the food industry

Description

BS not only supplies the food industry with slicers and sandwich cutters, but also provides different sized conveyor belts or work surfaces.

The special feature of these belts is that the tubes at a 45° angle are welded, for easier cleaning.

The belt can be disassembled and re-assembled very quickly (around 1 minute) without having to use any tools. This operation is allowed as the structure is built with a cantilevered part.

Another feature is that the surface of the belt has rods placed diagonally, while the two central rods, which act as guides, are placed lengthwise.

A K 10 belt is vulcanized on the surface for perfect belt centering, and the edges are also sealed upon request.

Belt tension is regulated by a pneumatic cylinder. An electric raceway can also be provided at a 45° angle, as well as sockets, depending on the power needs of other work stations.

Features

The electric panel has a differential gear for each socket, an inverter to control the belt, a seven-speed selector (with speeds stored) and two centesimal timers to manage the pacer and rotation star.

In addition to the electrical system, there is a manifold for air distribution with an outlet for each socket.

Optionals

A second belt can also be provided on request, to speed up production changes without downtimes, or equipment for automatic washing and sanitation of the belt.

Other optionals available on request include: butter spreader and surfaces to hold containers with sandwich fillings.

To overcome any particular unevenness, these belts are also quick to reassemble.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.