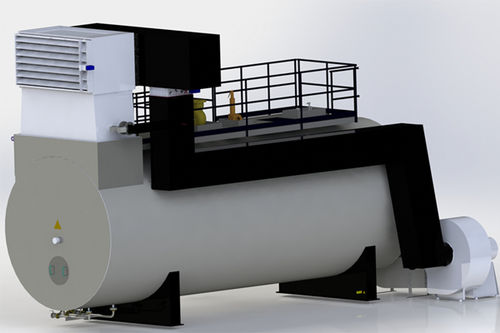

Energy saving and efficiency are key factors for modern industry. One of the most significant energy users in a typical production facility is the boiler and, recognising this, Babcock Wanson offers the R-ECO solution, which provides improvements in boiler efficiency of up to 98%*. The R-ECO is a combination of two technologies:

Combustion air pre-heating: This technology on its own increases the overall boiler but it can also increase the NOx emission.

Flue Gas Recirculation (FGR): FGR helps reduce the formation of NOx emissions in the flue gas to ensure compliance with environmental regulations.

Principle of operation: Exhaust Gas Combustion Air Preheating Economiser

The benefits of “R-ECO” installation are most apparent where there is greater than 90% condensate return. As returning condensate is already at high temperature this makes it unsuitable for use with classic feedwater economisers. Other operating conditions required for successful R-ECO operation are flue gas inlet temperature above 130 ° C, flue gas temperature output ≈ 100 ° C, and Natural Gas fuel.

Construction: Aluminium Exchanger Plate

Casing: Galvanized steel

Operating Conditions

No other heat recovery sink than combustion air (e.g. in the case of condensate return ≥90%)

Exhaust Gas Inlet Temperature ≥ 130 ° C

Exhaust Gas Outlet Temperature ≈ 70 °

Fuel – Natural Gas

For a boiler feed water temperature ≥ 110 ° C an approximate efficiency gain of 2.5%*

For a boiler feed water temperature ≥ 105 ° C an approximate efficiency gain of 3%*