- Products

- Catalogs

- News & Trends

- Exhibitions

5-axis machining center JETverticalfor wood

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Machined material

- for wood

Description

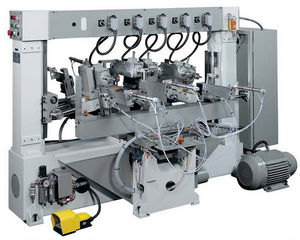

CNC Machining Center with 5 Full digital interpolated axes, suitable for different applications such as:

- Tenoning

- Finger Jointing

- Drilling

- Mortasing

- Milling

- 4/5 axes profiling

The JET machining center is equipped with one operating unit with 2/3/4 spindles, each one with 7.5 kw power and ceramic bearings.

The particular axes motion allows the machining of five faces of a wooden piece with little movements but with high acceleration due to the strong rigidity of the machine.

Jet is also equipped with 3 clamps from the bottom to the top in order to clamp with a single adjustment both RH and LH pieces; loading and uloading of pieces (manual or robotized) occurs in two decentralized positions.

The machine can be equipped with one or two newly designed and patented.

Main features:

- Single clamping system for both R.H. and L.H. chair legs.

- New double reference system for R.H. and L.H. chair legs.

- Total exposure of the piece side with a larger number of machinings performed. This can be also used as reference surface.

- Support placed at an ergonomic height, on which machined pieces are lined up in order and without collisions. R.H. pieces are separated from L.H. pieces.

- Very easy operation of manula loading and unloading of pieces (both R.H. and L.H.). Also useful for the execution of samples.

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 2-axis turning center

- 5-axis CNC machining center

- Gantry CNC machining center

- High-productivity CNC machining center

- Horizontal CNC machining center

- Universal CNC machining center

- Steel CNC machining center

- Wood CNC machining center

- Multi-spindle turning machine

- 6-axis CNC machining center

- Mortising machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.