- Industrial machines and equipment

- Heat Exchanger and Refrigeration

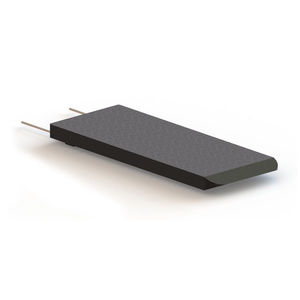

- Metal hot plate

- Bach Resistor Ceramics GmbH

Metal hot plate ceramicelectricprecision

Add to favorites

Compare this product

Characteristics

- Material

- ceramic, metal

- Other characteristics

- electric, precision

- Temperature

Min.: 500 °C

(932 °F)Max.: 1,000 °C

(1,832 °F)

Description

Ceramic hot plates made of silicon nitride can be produced with an outer diameter of 400 mm. Within this diameter any rectangular shape, customized shape or opening is possible. A typical height of the plates is 5 mm. The special properties and low mass of the ceramic material allow fast heating rates, uniform temperature distribution and outstanding precision in control. In comparison to metal the surface of ceramic material stays flat due to its low thermal expansion even when operated with fast changes in temperature. The high strength of hot-pressed silicon nitride guarantees high stress resistance (e. g. with high pressure loads) and excellent wear resistance. We provide hot plates for operating in the open air at temperatures up to 500 °C. Temperatures up to 1 000 °C could be achieved by developing specific technical solutions. However with continuous operation at temperatures > 900 °C a limited service life of 2 500 operating hours is to be expected, whereas with operation under high vacuum even at 1 000 °C the wear and tear is very low.

Customized design

Our in-house designs make any modification in size, configuration, or performance simple and convenient. Mounting-bracket holes and bores for temperature sensors can be added to the design. Laser-cut vacuum grooves can be added as well. Our hot plates come already flat ground, however they can be ground further up to a flatness of < 10 μm to meet specific requirements. A variety of shapes formed to the contour of the product or tool to be heated are possible as well. Furthermore, our ceramic heating conductor with its customized design allows the integration of several heating zones.

Catalogs

No catalogs are available for this product.

See all of Bach Resistor Ceramics GmbH‘s catalogsOther Bach Resistor Ceramics GmbH products

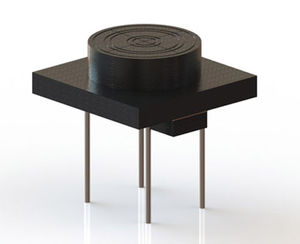

Ceramic heating elements

Related Searches

- Resistance heater

- Heater

- Electric heater

- Cartridge heater

- Flat resistance heater

- Ceramic resistance heater

- Metal hot plate

- Igniter

- Electric hot plate

- Ceramic hot plate

- Precision hot plate

- Piping heater

- Flat heater

- Round heating element

- Burner igniter

- Soldering hot plate

- Gas igniter

- Ring heating element

- Fuel oil igniter

- Ceramic igniter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.