Gas turbine Frame 5/1PAfor power generationsingle-shaft

Add to favorites

Compare this product

Characteristics

- Type

- gas

- Applications

- for power generation

- Other characteristics

- single-shaft

- Rated power kW

25,500 kW, 26,600 kW

(34,670.34 hp, 36,165.92 hp)

Description

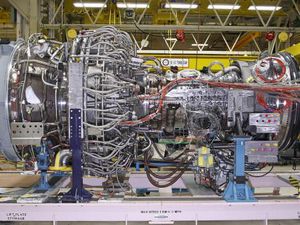

Single-shaft gas turbine built on a solid foundation with best-in-class availability and reliability

Benefits

Excellent availability and reliability as a prime mover; designed for long life

Enhanced fuel flexibility with no impact on combustor’s operability or integrity

Compact package design for easier maintenance; single-lift basement for engine and auxiliaries

Features

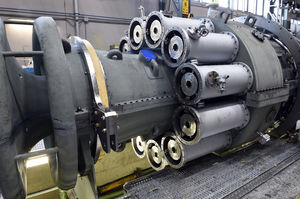

17-stage axial compressor adopted on former N, P, and PA models

Multi-can DLN1 combustion system with dual-fuel capability for STD/LHE

Single-shaft turbine hot-end drive architecture; two-stage turbine with uncooled buckets

Applications

Refinery, petrochemical, and fertilizer

Industrial, and combined heat and power

At ISO conditions with natural gas fuel, ambient temperature 15°C, no inlet exhaust losses, sea level, 60% relative humidity. Assuming average efficiency of gearbox and generator. Package dimensions include driven equipment.

Fuel flexibility

A single-chamber, full-scale test campaign was conducted on DLN1 hardware to assess the combustor’s capability to operate with increasing C2+ levels in the fuel gas. Standard hardware currently installed on Frame 5/1PA DLN1 units are suitable to burn fuel gases with up to 40% C2+ (C2 to C4 alkanes) with no issues for the combustor’s operability or integrity.

Fuel composition

The Frame 5/1PA DLN1 can burn heavy hydrocarbons (25% max ethane content or 20% max propane), inerts (25% max CO2 or 25% max N2), hydrogen up to 20%, liquid fuel (distillate #2 at 42 ppm wet).

Performance enhancement

Maintenance plan enhancement (35,000/70,000 hours) can be provided as an option on the standard/LHE configuration.

Catalogs

No catalogs are available for this product.

See all of Baker Hughes‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.