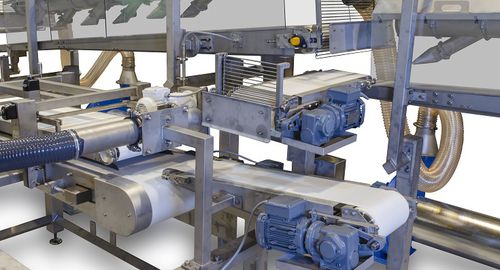

Standard proving arrangements and intermediate conveyors can been replaced by a special purpose flour-free resting system that uses a variety of techniques to ensure the dough pieces are fully rested yet transfer cleanly from the divider to the moulder.

The system fulfils two functions. Firstly, to transport the dough pieces from the upstream forming equipment and, secondly, to allow the dough pieces to rest.

Exact specification for all dough types

To prevent adhesion, Baker Perkins’ flour-free systems use multi-stage conveyors with transfers, belt materials and air systems carefully selected to suit the resting time, dough properties and ambient conditions.

Achieving the correct balance is critical: if the steps taken to avoid adhesion go too far, the dough pieces may not relax sufficiently, or be misshapen or too dry to mould well. Baker Perkins' experience enables our process engineers to specify systems that balance all of the parameters to ensure that the dough pieces arrive at the moulders in perfect condition to produce high quality, consistent loaves.

Precision resting times for optimal dough

The resting step is a vital part of the process, as it relaxes the stresses that build up in the dough pieces during the dividing process. Without relaxation, the dough pieces are prone to tearing during the moulding process and also to proof and bake unevenly.

The size of the system is determined by the resting time required. Careful consideration has to be given to the design of the system to ensure that the dough pieces do not have time to stick to the dough-handling elements.