The composite pipe has been widely used in many fields. Continuous Steel Ribbed Polyethylene Pipe (SRPP) has specific advantages of corrosion resistance, anti-settling, long service life, convenient transportation and construction installation with lower costs

By Comparing with traditional steel wired reinforced composite pipe, this brand new composite pipe machinery technology supported by US national standards, with nearly 30 to 40 years of experience in the United States. Under Analysis and verification of the quality & service life for this kind of pipe. the pipe service life can be reached 80 years

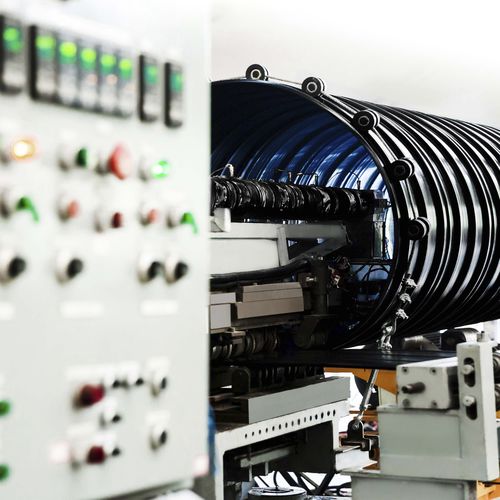

Production Line Features

Since it uses polyethylene raw material is not high, similar with the steel wired pipe, Saving at least 30-50% more by comparing with Carat Pipe. Faster composite pipe machinery production speed under lower costs, higher automation degree that makes the employment cost lower.

Lower Manufacturing Cost

The composite pipe machinery can be pulled to the site for production if meet required environment condition, which reducing the pipe transportation cost. There is no need to change the mold to manufacture any diameters between 600mm – 3000mm. Compared with the double wall bellows, steel wired reinforced pipes and Carat pipes, the production efficiencies are well considered since there’s no need to temporally pause the machine in order to change the mold.

Lower Composite Pipe Machinery Cost

SRPP has convinent production procedure, one equipment can produce 600mm+ Pipe caliber. If modified to one equipment with three sets of devices that can produce any specification pipes between 600mm – 3000mm caliber.