- Environment - Health - Safety

- Waste Treatment

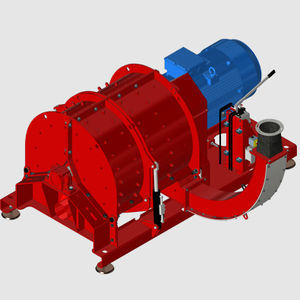

- Primary shredder

- BANO RECYCLING SRL

Primary shredder PREMAC HYDRO seriessingle-shaftmetalrugged

Add to favorites

Compare this product

Characteristics

- Type

- primary

- Number of shafts

- single-shaft

- Application

- metal

- Other characteristics

- rugged

- Power

Max.: 355,000 W

Min.: 132,000 W

- Rotor diameter

Max.: 900 mm

(35 in)Min.: 700 mm

(28 in)- Operating weight

Max.: 45 t

(49.6 us ton)Min.: 25 t

(27.6 us ton)

Description

Thanks to the development of the Premac range, Bano Recycling offers advanced solutions for the

metal scrap classification and recovery.

Compared to traditional systems, our plant offers the option of working with a screen during the

shredding process to set a desired output size; this gives the great advantage to have a secondary raw

material in just one step.

Performaces are greatly increased thanks to the presence of the pusher that keeps a constant and self-

regulated rotor feeding. Maintenance is extremely simplified due to the moving floor installed, it is also

safer and with very low running costs.

Solidity and high throughput capacity stick together with practicality, versatility and simplicity of maintenance.

Characteristics:

• - Hydraulic or mechanical drive system

• - Sliding hopper bottom for safer and quicker maintenance

• - Interchangeable and reversible Blades and counter-blades for a quick and cheaper replacement

• - Safety Clutch on transmission (only mechanical version)

• - Machine structure 100 mm

• - Pusher for increased production

• - Active Protection system for bearings

• - Interchangeable screen with different size holes

• - Patented rotor design, studied to increase performances

• - Anti-vibrating support system

Catalogs

No catalogs are available for this product.

See all of BANO RECYCLING SRL‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Waste shredding machine

- Single-shaft shredding machine

- Primary shredding machine

- Gravity classifier

- Classifier for the recycling industry

- Metal shredding machine

- Particle classifier

- Rugged shredding machine

- Compact classifier

- Cyclone classifier

- Mobile shredding machine

- Cable shredder

- Waste recycling classifier

- Decantation separator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.