- Hydraulics - Pneumatics

- Filter and Separator

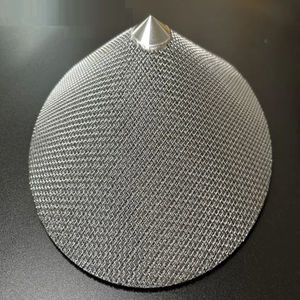

- Stainless steel filter medium

- Baoji Yinggao Metal Materials Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Stainless steel filter element gasliquidsintered

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Applications

- liquid, gas

- Other characteristics

- sintered

- Pore size

Min.: 0 µm

Max.: 0.22 µm

Description

Porous sintered metal filters are constructed from interconnected networks of uniformly distributed pores, creating intricate pathways that effectively capture solid particles present in gas or liquid flow streams. These filters are renowned for their exceptional mechanical strength and serve as outstanding depth filters. Type 316L stainless steel, known for its robustness, can endure temperatures up to 750°F (399°C) in oxidizing environments and 900°F (482°C) in reducing environments.

The production of sintered metal filters involves employing 316L stainless steel powder. The manufacturing process entails the uniaxial compaction of powder within a rigid tool possessing the inverse shape of the desired part, followed by sintering. By adjusting the compaction pressure and/or particle size of the powder, the pore size of the filter can be precisely controlled.

Products Applications

Chemical Industry: The filter ring finds extensive use in the chemical industry for processes such as catalyst recovery, polymer filtration, and solvent purification.

Food and Beverage Industry: It is employed in the food and beverage industry for filtering liquids, including juices, syrups, and edible oils, ensuring product purity and quality.

Pharmaceutical Industry: The filter ring plays a critical role in pharmaceutical manufacturing, providing sterile filtration for drugs, vaccines, and other pharmaceutical products.

Petrochemical Industry: It is utilized in the petrochemical industry for the filtration of various fluids, including crude oil, refined petroleum products, and specialty chemicals.

Other Baoji Yinggao Metal Materials Co., Ltd. products

Microporous Filter Components and Microporous Filter Elements

Related Searches

- Filter cartridge

- Industrial filter cartridge

- Fine filter cartridge

- Water filter cartridge

- Filter element

- Pleated filter cartridge

- Chemical product filter cartridge

- Gas filter element

- Chemical filter cartridge

- Liquid filter element

- Metal filter cartridge

- Oil filter cartridge

- Foodstuff filter cartridge

- Beverage filter cartridge

- High-flow filter cartridge

- High-efficiency filter cartridge

- Food filter cartridge

- Filter cartridge for food applications

- Solvent filter cartridge

- Filter cartridge for chemical applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.