- Production Machines

- Plastics Processing

- Sheet extrusion line

- battenfeld-cincinnati USA

- Products

- Catalogs

- News & Trends

- Exhibitions

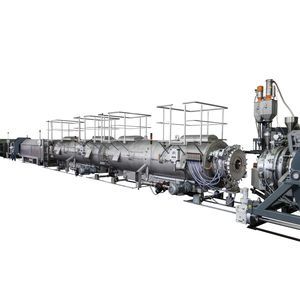

Sheet extrusion line for PVC

Add to favorites

Compare this product

Characteristics

- Type

- sheet

- Treated material

- for PVC

Description

Complete lines from a single source

Resource-saving and economical production

battenfeld-cincinnati offers complete lines for PVC sheet extrusion with perfectly coordinated machine components that feature high output combined with consistent excellent end product quality.

Your Advantages:

*Customized extruder sizes for all requirements: twinEX 114, 135, 173 and conEX for co-extrusion

*Special PVC feed block for 3-layer or 2-layer sheets

*Adjustable pre-cooling unit for free foamed sheets consisting of three pairs of cooled free foamed sheet rollers

*Inline flat sheet thickness measuring system

*Intensive cooling unit for thick foam sheets

*Protection film unwinder for both sheet surfaces

*Dust-free knife cutting unit for edge trimming

*Side strip guillotine cutter with belt conveyor system

Our Offer:

*Complete lines from a single source

*Worldwide technical and processing support from battenfeld-cincinnati

*State-of-the-art formulation for newcomers

*Computer-based die melt channel design

*Fast gap system and central gap adjustment

*Accurate polishing roll temperature distribution (+/- 0.5 °C)

*Output performance from 400 kg/h up to 2,000 kg/h, depending on sheet thickness and extruder type

Catalogs

No catalogs are available for this product.

See all of battenfeld-cincinnati USA‘s catalogsOther battenfeld-cincinnati USA products

Downstream & Systems

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Maplan extruder

- Pipe extrusion line

- Plastic sheet extrusion line

- PVC extrusion line

- Twin-screw screw extruder

- Multilayer extrusion line

- Maplan single-screw extruder

- HDPE extrusion line

- Extrusion line with water cooling

- Maplan PP extruder

- Plastic profile extrusion line

- Maplan PVC extruder

- Single layer extrusion line

- PE screw extruder

- ABS screw extruder

- Compact screw extruder

- PS screw extruder

- High-throughput extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.