- Production Machines

- Plastics Processing

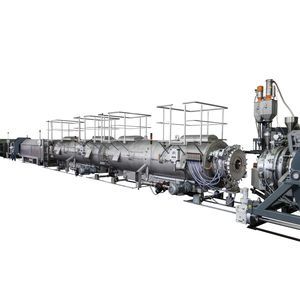

- Tube extrusion line

- battenfeld-cincinnati USA

- Products

- Catalogs

- News & Trends

- Exhibitions

Pipe extrusion line for thermoplasticswith water coolingwith air cooling

Add to favorites

Compare this product

Characteristics

- Type

- for pipes

- Treated material

- for thermoplastics

- Other characteristics

- with water cooling, with air cooling

Description

Saving energy all along the line

The innovative concept for energy efficient pipe production

Optimizing only the extruder is not sufficient for sustainable energy consumption cuts on the entire extrusion line. All line components must make a contribution. Therefore, battenfeld-cincinnati offers an energy monitoring system to ascertain exatly how to optimize each line component. In addition, we have also developed the innovative "Green Pipe" concept which can significantly increase energy-efficiency for pipe production.

Green Pipe downstream concept

Energy consumption of cooling section can be almost halved

Cooling water consumption per hour can be reduced by almost 90 %

"Free Cooling" can be increased by up to 50 %

Green Pipe components

helix II VSI-T pipe die with Efficient Air Cooling" EAC:

Effective internal pipe cooling with EAC (Efficient Air Cooling): ambient air flows through the pipe against the direction of extrusion and thus cooling the pipe evenly from the inside

Depending on the application, the length of the cooling section can be reduced by 30% to 50%

Integration into existing extrusion lines is possible after consultation

Most existing battenfeld-cincinnati pipe heads can be retrofitted

EAC drying system (Labotek):

Jointly developed with battenfeld-cincinnati for the use of helix II VSI-T pipe dies

Energy-efficient EAC combination dryer system

The drying system operates with two separate drying zones

Catalogs

No catalogs are available for this product.

See all of battenfeld-cincinnati USA‘s catalogsOther battenfeld-cincinnati USA products

Downstream & Systems

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Maplan extruder

- Plastic sheet extrusion line

- Twin-screw screw extruder

- Pipe extrusion line

- Multilayer extrusion line

- PVC extrusion line

- Maplan single-screw extruder

- HDPE extrusion line

- Maplan PP extruder

- Plastic profile extrusion line

- Maplan PVC extruder

- Single layer extrusion line

- PE screw extruder

- ABS screw extruder

- Compact screw extruder

- Extrusion line with water cooling

- PS screw extruder

- High-throughput extrusion line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.