- Materials - Tools - Components

- Automotive maintenance equipment

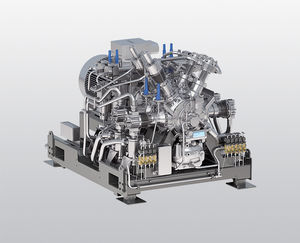

- Piston compressor

- BAUER KOMPRESSOREN GmbH

Water-cooled compressor I series pistonairnatural gas

Add to favorites

Compare this product

Characteristics

- Technology

- piston

- Type

- air, nitrogen, natural gas, helium

- Power source

- electric

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial

- Other characteristics

- high-pressure, heavy-duty, air-cooled, water-cooled, four-stage

- Pressure

90 bar, 365 bar, 420 bar

(1,305.34 psi, 5,293.88 psi, 6,091.58 psi)- Flow

Min.: 1,300 l/min

(343.42 us gal/min)Max.: 6,600 l/min

(1,743.54 us gal/min)- Power

Min.: 30 kW

(40.79 hp)Max.: 160 kW

(217.54 hp)- Weight

Min.: 1,000 kg

(2,204.6 lb)Max.: 4,900 kg

(10,802.7 lb)

Description

Cooling of valve heads reduces thermal load: For minimum wear

Installation even under the most difficult ambient conditions: Thanks to dedicated water cooling of the compressor block

Incredibly long-serving and reliable unit: With extended valve service life and low oil consumption

Reduced noise level: Compared with air-cooled units

BAUER I-series water-cooled high-pressure compressors are ideal for installation under the most difficult ambient conditions as well as for use in industrial applications.

By using targeted water cooling between the interstage and afterstage coolers and valve heads, the system enables the majority of the heat produced to be absorbed by the cooling water.

As a result, the multi-stage, industrial high-pressure compressors require very little maintenance and achieve long service lives. At the same time, they are quieter than comparable air-cooled compressors.

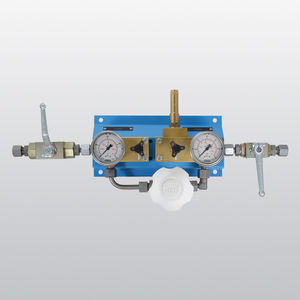

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions.

Compressor block

For compressor units with intake pressure, the BK 23 to BK 52 block series feature a pressure-tight crankcase for uniform absorption of the internal gas forces

Water cooling

By using targeted water cooling between the interstage and afterstage coolers and valve heads, the system enables the majority of the heat produced to be absorbed by the cooling water. This maintenance-friendly cooling concept is suitable in particular for difficult spatial and ambient conditions where it would not be possible to use an air-cooled compressor.

VIDEO

Catalogs

Related Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Reciprocating compressor

- Oil-injected compressor

- Compact compressor

- Mobile compressor

- Low-noise compressor

- Cooled compressor

- Multi-stage compressor

- Gas compressor

- Oil-lubricated compressor

- Air-cooled compressor

- High-pressure compressor

- Portable compressor

- Rugged compressor

- Belt-driven compressor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.