- Production Machines

- Plastics Processing

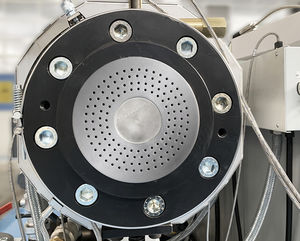

- Discontinuous screen changer

- Bausano & Figli S.p.A.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Discontinuous screen changer belthydraulicautomatic

Add to favorites

Compare this product

Characteristics

- Type

- discontinuous

- Technology

- belt

- Operation

- hydraulic

- Options

- automatic

Description

Each line is complete with cooling and calibration benches, take off and cutting units, each featuring special measures to achieve additional energy savings up to 50%!

Single or double output heads

Each extrusion head is manufactured to meet the specific needs and process parameters of each processed material and desired final product. They are equipped with interchangeable pins and bushings to speed up the change of measurement and of special spokes, designed to optimise the flow of the thermoplastic material.

Completely thermoregulated both externally and internally and made of chromed or stainless steel, the heads can be single or double output with predisposition for co-extrusion with one or more auxiliary inputs.

Calibration bench

Manufactured according to the product characteristics and made of stainless steel, it ensures the total absence of corrosion and allows maximising extrusion pipe productivity.

Cooling bench

Designed for cooling of pipes with diameter up to 1,000 mm, it allows reaching high extruded material linear speeds, ensuring the maximum dimensional stability.

The ease of adjustment on 3 axes and the motor-driven longitudinal movement allow a quick and precise positioning during machining.

Take off unit

Take off pipes with 2, 3 or 4 tracks, with flat and shaped rubber pads, complete the lines.

Take off units

Special units with useful pick-up devices in length and width able to meet any special needs.

Cutting unit

Modular and ergonomic unit, provided with automatic pneumatic movement that does not require manual operation for adjustments such as cut length, trolley forward and backward speed.

Catalogs

No catalogs are available for this product.

See all of Bausano & Figli S.p.A.‘s catalogsRelated Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Bausano extruder

- Bausano twin-screw extruder

- Pipe extrusion line

- Plastic pelletizer

- Multilayer extrusion line

- Single-screw screw extruder

- Polypropylen extrusion line

- Polyethylene extrusion line

- Bausano PP extruder

- HDPE extrusion line

- Bausano PE extruder

- Bausano ABS extruder

- Plastic profile extrusion line

- Bausano PVC extruder

- Compact screw extruder

- Pelletizer for the plastics industry

- Laboratory screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.