- Packing - Handling - Logistics

- Packing and Packaging

- PLC-controlled labeler

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

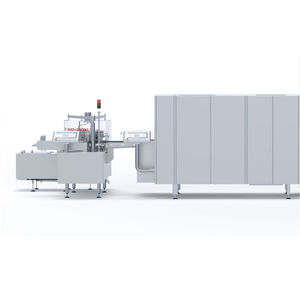

PLC-controlled labelling machine ESF Seriesfor bottlesfor self-adhesive labelscompact

Add to favorites

Compare this product

Characteristics

- Operational mode

- PLC-controlled

- Product application

- for bottles

- Type

- for self-adhesive labels

- Other characteristics

- compact, continuous-motion

- Throughput

12,000 p/h, 21,000 p/h, 30,000 p/h

- Product height

Min.: 35 mm

(1.38 in)Max.: 240 mm

(9.45 in)

Description

Labeling machine ESS 1001 applies self-adhesive labels off the roll to disposable syringes and inserts plunger rods into disposable syringes. This continuous-motion machine has a highly compact design. All electrical, electronic and PLC components are integrated in the machine to save space. The label dispenser has a modular design and can be equipped with both intermittent-motion printing systems and continuous-motion printing systems. The basic equipment of the label dispenser ensures that containers are labeled exactly and gently. To provide more convenience and reliability, the functionality of the label dispenser can be increased by a series of additional checking devices and workstations.

•High process reliability

•Compact design

•Consistent and reliable labeling

•Modular label dispenser design

•Short set-up time

•Easy and centralized operation

•Gentle container transport

•Label code scanner

•Various printers (e.g. hot foil printers, thermal transfer printers, laser printers, etc.)

•Pressure relief station

•Print check system

•Image processing system for 100 % inspection of printed data such as batch number, date of expiry etc., or of the complete label print.

•Label-on-container checks for luminescent or non-luminescent labels

•Automatic empty space recognition when labels are missing on the web

•Backstop application station

•Equipment for processing needle trap labels

•Label splicer system

•Reject discharge for faulty containers

•Options for interlinking with machines upstream or downstream

•Service portal vision system (cleanroom compatible)

•A range of checking and alarm devices and counters

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.