- Packing - Handling - Logistics

- Packing and Packaging

- Bottle filling and closing machine

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

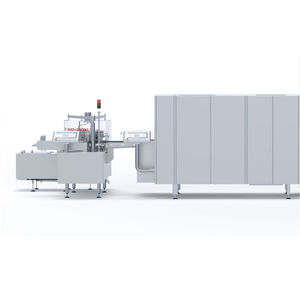

Bottle top filling and closing machine FFV 12024bottlefor pharmaceutical applications

Add to favorites

Compare this product

Characteristics

- Container type

- bottle top, bottle

- Applications

- for pharmaceutical applications

Description

The machine type FFV 12024 comprises a compact system for filling and closing vials, bottles and similar containers. The dosing station is designed to process liquid products using rotary piston pumps. However, it can also be equipped with alternative dosing technology such as peristaltic pumps or a time-pressure dosing system. The containers are conveyed through the work area in a continuous motion and suspended freely, without any obstruction by base guides or counterguides. This LF-friendly transport system works virtually particle-free. The containers are closed by the insertion of rubber stoppers or droppers.

•Pharmaceutical design

•Gentle container transport

•Continuous, reliable and gentle closing system

•Size change without tools

CIP/SIP

"Cleaning in place – sterilizing in place" is a system for cleaning and/or sterilizing product-carrying parts as installed. Our CIP/SIP system offers a high level of process reliability while saving work and time, as well as cutting cleaning and sterilization costs.

All parts which come into contact with the product are rinsed intensively with suitable cleaning media. There is no need to remove any parts. Once the cleaning and sterilization process has been completed, the entire system is cooled and kept under vacuum until the start of production. All applicable technical and pharmaceutical regulations, such as DIN, GMP and FDA, are observed and applied.

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.