- Packing - Handling - Logistics

- Packing and Packaging

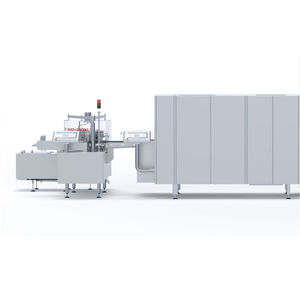

- Bottle top filling and closing machine

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Bottle top filling and closing machine FVF Seriesfor pharmaceutical applications

Add to favorites

Compare this product

Characteristics

- Container type

- bottle top

- Applications

- for pharmaceutical applications

Description

The FVF series consists of compact lines for filling and closing vials and similar stable bottles made of glass, plastic or metal. The machine is designed for a broad range of applications. Both liquid and powder products can be filled by using different dosing systems. The containers are conveyed through the work area in an intermittent motion by a walking beam system which handles the containers particularly gently. The number of transport positions is variable, which means that these systems have a wide processing range. A further special feature: 100% IPC at full output.

•Liquid or powder products

•Gentle container transport

•100 % IPC at full output

•Up to two different types of closure

•Easy and centralized operation

•Short set-up time

•Pharmaceutical design

•Gentle container transport

• Barrier systems - RABS and cleanroom isolator

• Processing non-stable containers

• Various dosing systems (e.g. peristaltic pumps, time-pressure dosing system,

powder dosing systems etc.)

• SIP/ClP-compatible dosing components

• ECOfill

• Zero-loss start-up and running empty With minimal product loss

• In-Process Control (IPC)

• Sample discharge

• Closure feed from supply system

• Service portal vision system (cleanroom compatible)

• A range of checking and alarm devices and counters

• Software upgrades

• Qualification (IQ/OQ)

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.