- Packing - Handling - Logistics

- Packing and Packaging

- Continuous-motion labeler

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

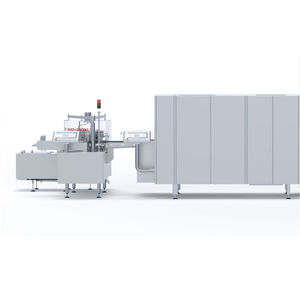

Continuous-motion labeling machine EOM 1025

Add to favorites

Compare this product

Characteristics

- Other characteristics

- continuous-motion

- Throughput

19,200 p/h

Description

The EOM 1025 is designed to label pens, such as those commonly used for self-medication, with a maximum of positioning accuracy. It can easily be configured for continuous processing of pens with guaranteed exact label alignment. Robot-assisted removal of the pens from the delivery trays is optional, as is further processing after labeling. Containers are transported very safely and gently throughout the process, and there is no pen-to-pen contact at any time.

The label dispenser has a modular design and can be equipped with both intermittent-motion printing systems and continuous-motion printing systems. The basic specification of the label dispenser ensures that insulin pens are labeled exactly, gently and in the correct position. For greater convenience and reliability, the functionality of the label dispenser can be enhanced with a range of additional checking devices and workstations.

•Compact design

•Consistent and reliable labeling

•High process reliability

•Modular label dispenser design

Properties

•Easy and centralized operation

•Short set-up time

•Gentle container transport

•Label code scanner

•Various printers (e.g. hot foil printers, thermal transfer printers, laser printers, etc.)

•Print check system

•Image processing system for 100 % inspection of printed data such as batch number, date of expiry etc., or of the complete label print.

•Label-on-container checks for luminescent or non-luminescent labels

•Label splicer system

•Transport chains at the infeed and discharge ends for individual feeding of pens into and out of the machine

•Tray full signal

•Various discharge systems for faulty containers

•Labeling repetition feature

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.