- Packing - Handling - Logistics

- Packing and Packaging

- Syringe filling and closing machine

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

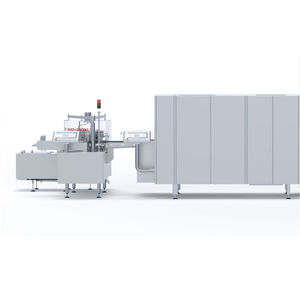

Syringe filling and closing machine SFM 5105for pharmaceutical applications

Add to favorites

Compare this product

Characteristics

- Container type

- syringe

- Applications

- for pharmaceutical applications

Description

Machine module SFM 5105 fills and closes nested containers such as cartridges and syringes in the VarioSys production system. The dosing station is designed to process liquid products using rotary piston pumps, but can also be equipped with alternative dosing technology such as peristaltic pumps. The module closes the containers fully automatically immediately after dosing. The insertable closures are processed reliably and gently. In accordance with the overall machine concept, this module is designed to feed closures to the pick-up position with absolutely minimal particle emission.

•Mobile, space-saving production system in an isolator

•Easy and centralized operation

•Low-particle closure feed

•Pharmaceutical design

•Compact design

•High process reliability

•Precise maintenance of production parameters

• Alternative dosing systems

• In-Process Control (IPC)

• Vacuum-assisted dosing

• Gas flushing with a controlled amount of gas during filling and closing

• Bin and feed unit for optimized closure supply

• Vacuum-assisted plunger stopper insertion

• A range of checking and alarm devices and counters

• Software upgrades

• Qualification (IQ/OQ)

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.