- Packing - Handling - Logistics

- Packing and Packaging

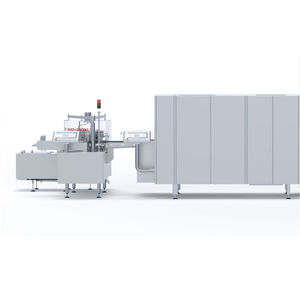

- Semi-automatic filling machine

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Semi-automatic filling machine EDM seriesfor glass containerssyringefor cartridges

Add to favorites

Compare this product

Characteristics

- Operational mode

- semi-automatic

- Container type

- for glass containers, syringe, for cartridges

- Product applications

- for liquids

- Domain

- for the pharmaceutical industry

- Type

- piston

- Other characteristics

- compact, tabletop

Description

Compact machines for simple and precise filling of all kinds of stable containers. Non-stable containers such as cartridges, syringe barrels and test tubes can be processed easily using transport stands. Our semi-automatic machines have been developed on the basis of our expertise in the design and construction of fully automatic systems for processing containers to pharmaceutical industry standards. Our dosing systems are identical to those used on fully automatic production lines and ensure that a consistently high standard of processing quality is achieved. Several dosing systems are available, such as a valveless rotary piston pump, our patented single-hose peristaltic pump or a ViscoTec Pharma Dispenser (for highly viscous products, among others). By the use of scales, an in-process control of up to 100 % is possible, with automatic feedback adjustment of the dose during production. Batch reports can be saved and printed using the printer supplied together with the machine equipment.

• Operation via a touch screen panel

• Suitable for H2O2 decontamination for use in an isolator

• Servomotor drive

• Scales for 1-100 % in-process control

• Pharmaceutical design

• Precise maintenance of production parameters

• Management of recipes

• EDM 3611 with technology (self-priming and run empty function without product loss, only the last container may need to be rejected)

• Vacuum-assisted dosing (not for EDM3295)

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact bagging machine

- Compact filler

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.