- Packing - Handling - Logistics

- Packing and Packaging

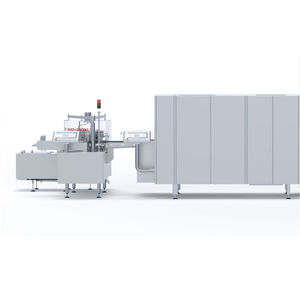

- Bottle top filling and closing machine

- Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Bottle top filling and closing machine KFM Seriesfor sterile applications

Add to favorites

Compare this product

Characteristics

- Container type

- bottle top

- Applications

- for sterile applications

Description

The machines and lines of the KFM series have been developed for processing cartridges. The machine concept provides scope for intermittent-motion rotary machines as well as continuous and intermittent-motion linear machines. Before filling, the plunger stoppers are inserted into the cartridges from below. The dosing station is designed to process liquid products using rotary piston pumps. However, it can also be equipped with alternative dosing technology such as peristaltic pumps or a time-pressure dosing system. The cartridges are filled to the brim in 2 stages by prefilling the cylindrical part of the cartridge, followed by final filling up to the top of the cartridge. The cartridges are then closed with crimp caps with a rubber seal.

Container transport without glass-to-glass contact

A special transport system transports the cartridges individually, safely and gently from the start to the end of the primary packaging process. This system ensures that the cartridges do not come into contact with one another at any time.

•High process reliability

•Pharmaceutical design

•Easy and centralized operation

•Optimal laminar air flow

• Barrier systems - RABS and cleanroom isolator

• Insertion of mixing beads

• Alternative dosing systems (e.g. peristaltic pumps, time-pressure dosing

system)

• SIP/ClP-compatible dosing components

• Gas-flushing stations

• Various supply hoppers

• Service portal vision system (cleanroom compatible)

• A range of checking and alarm devices and counters

• Software upgrades

• Qualification (IQ/OQ)

Other Bausch + Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG products

Machines

Related Searches

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Automatic bagging machine

- Bottle labeling machine

- Semi-automatic filler

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Piston filler

- Compact filler

- Compact bagging machine

- Compact labelling machine

- Powder filler

- Automated sealing machine

- Auger filling machine

- PLC-controlled labeling machine

- Bench-top filler

- Filling and closing machine

- Aseptic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.