- Metrology - Laboratory

- Metrology and Test Equipment

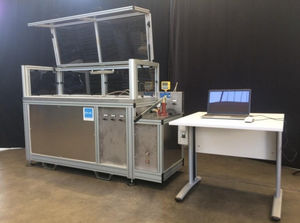

- Flow test bench

- BAVA TESTING SOLUTIONS

Flow test bench B_21693automaticPLC-controlledfor nozzles

Add to favorites

Compare this product

Characteristics

- Test type

- flow

- Operating mode

- automatic, PLC-controlled

- Test material

- for nozzles

- Sector

- for the aerospace industry

- Other characteristics

- custom, with touchscreen

Description

Bench designed for testing lubrication nozzles.

The bench consists of a metal structure with glazed front doors, the upper part for mounting nozzles in test, the lower part for the weighting group and the fluid recovery and conditioning tank.

The test bench is completed by the DAS console and the electrical panel. The control and signaling console incorporates all the control functions for the execution of the test.

• Fluid: olio MIL L 23699;

• Temperature: 30 ÷ 120 °C;

• Pressure: 1500 kPa;

• Flow: 25 lpm;

• Measure time: 0 ÷ 5 min;

• Max no. of jets per nozzle: < 8.

INSTRUMENTATION:

• Pressure: f.s. 10 bar, cl. 0,05%;

• Flow: f.s. 25 lpm, cl. 0,05%;

• Temperature: sonde PT100, cl AAA;

• Weight: 20 Kg, accuracy cl. 0,05%.

SAFETY DEVICES:

• Inhibition of the exhaust circuit bench;

• Interlock on test compartment hatch;

• Mushroom emergency button;

• Automatic interruption of the test in case of breakage,

component leakage or malfunction of the bench;

• Maximum pressure valve;

• Thermostat of maximum temperature.

Catalogs

AEROSPACE

16 Pages

Other BAVA TESTING SOLUTIONS products

LEAK, PRESSURE AND BURST TEST STANDS

Related Searches

- Test cabinet

- Test stand

- Automatic test stand

- Pressure test stand

- Industrial test bench

- PC-controllable test bench

- Hydraulic test stand

- Manual test stand

- Test stand for the automotive industry

- Leak test stand

- Valve test stand

- PLC-controlled test stand

- Pneumatic test stand

- Torque test stand

- Hose test stand

- Performance test stand

- Test stand for the aeronautical industry

- Engine test chamber

- Flow test stand

- Force test stand

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.