- Metrology - Laboratory

- Metrology and Test Equipment

- Temperature test bench

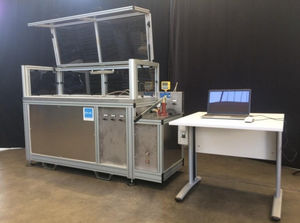

- BAVA TESTING SOLUTIONS

Pressure test bench B_19699temperatureflowcomputer-controlled

Add to favorites

Compare this product

Characteristics

- Test type

- pressure, temperature, flow

- Operating mode

- computer-controlled

- Test material

- vehicle

- Sector

- for the automotive industry, agriculture

- Technology

- hydraulic

- Other characteristics

- custom

Description

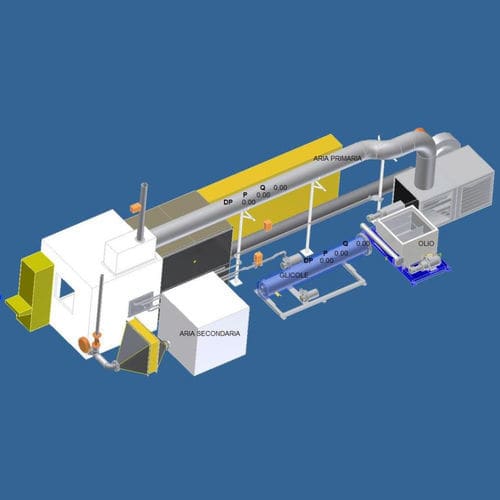

Test bench designed for heat exchanger testing:

• Efficiency;

• Dp of mass flow;

• DT.

The system consists of 4 circuits (primary air, secondary air, water / glycol mixture, oil), all controlled in flow, pressure and temperature to simulate and test radiators operating conditions (cars, heavy vehicles, agricultural machinery, special applications). All operations are controlled by the control console, which also includes the DAS (data acquisition system) and test report recording.

MAIN AIR:

from Ambient up to 50° C ±1° C;

Mass flow 1.500 ÷ 20.000 Kg/h;

Hydraulic head (plenum output) 1300 Pa (max flow).

SECONDARY AIR:

Inlet temperature 175° ÷ 230° C ±1° C;

Mass flow 180 ÷ 1.800 Kg;

Inlet hydraulic head 90 kPa.

LIQUID SIDE 1:

Type Water/glycol moisture

Max temperature 80°C ÷ 125°C ±1°C;

Power 140 kW;

Flow 2.000 ÷ 20.000 l/h

Max flow head hydraulic > 35 kPa (heat exchanger connections).

OIL:

Type ISO VG46;

Max temperature 70° ÷ 130° C ±1° C;

Power 30 kW;

Flow 500 ÷ 10.000 l/h;

Max flow pressure ~ 1 bar (heat exchanger connections) .

Catalogs

No catalogs are available for this product.

See all of BAVA TESTING SOLUTIONS‘s catalogsOther BAVA TESTING SOLUTIONS products

LEAK, PRESSURE AND BURST TEST STANDS

Related Searches

- Test stand

- Automatic test stand

- Pressure test stand

- Industrial test bench

- PC-controllable test bench

- Valve test stand

- Hydraulic test stand

- Manual test stand

- Test stand for the automotive industry

- Leak test stand

- PLC-controlled test stand

- Pneumatic test stand

- Torque test stand

- Hose test stand

- Test stand for the aeronautical industry

- Precision test stand

- Force test stand

- Performance test stand

- Flow test stand

- Motor test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.