- Metrology - Laboratory

- Metrology and Test Equipment

- Temperature test bench

- BAVA TESTING SOLUTIONS

Pressure test stand B_23092flowtemperaturecomputer-controlled

Add to favorites

Compare this product

Characteristics

- Test type

- pressure, flow, temperature

- Operating mode

- computer-controlled

- Test material

- for coolers, for electric drive

- Sector

- for the automotive industry

Description

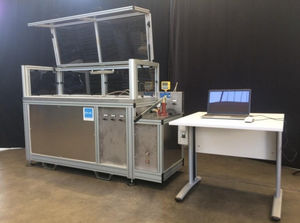

B_23092 station is built for the measurement of the hydraulic parameters of powertrain cooling system of thermal, hybrid and/or electric vehicles.

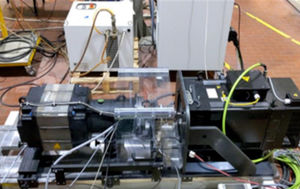

The tests involve the installation of the measurement sensors on a special test bench (already existing) that reproduces the layout of cooling system of the powertrain installed on the vehicle. The surveys are carried out using water/glycol mixture at room temperature.

Pumps (LIN or PWM) are fed with glycol water mix, at different temperature to simulate working conditions.

It’s possible to run the pump at different speed or with a speed profile.

Flow, pressure, temperature, power and speed are recorded.

By PC panel it’s possible to control:

• Flow, mixture pressure, temperature, power and speed

• Test time and test steps profile

TECHNICAL DATA:

• Pressure: 4 barg (max)

• Flow: 400 ± 2 lpm (max)

• Temperature: 80 ± 2 °C (max)

INSTRUMENTATION:

• Flow meters: n° 12, DN4 ÷ DN32

0 ÷ 200 lpm; 0,2% f-s accuracy

• Pressure transmitters: n° 10 relatives, -1 ÷ 4 barg, accuracy 0,04% f-s;

n° 2 absolutes, 0 ÷ 5 barabs, accuracy 0,04 f-s.

• Temperature transmitters: 0 ÷ 120 °C, PT100, cl. AAA

• Function generator: 0,1 ÷ 5 MHz, ± 20 ppm, 1 kΩ

• Power supply: 0 ÷ 80 V, 0 ÷ 20 A

SAFETY DEVICES:

• Emergency mushroom button

SUPPLY:

• Electric: 400 Vac - 50 Hz – 13 kW

DIMENSIONS AND WEIGHT:

• L, p, h: 1200 x 1033 x 2005 mm;

• Total raw load: ~ 280 kg

COLOR:

• Standard: Gray 7035.

NOTE:

• Fluid and adapters not included

Catalogs

No catalogs are available for this product.

See all of BAVA TESTING SOLUTIONS‘s catalogsOther BAVA TESTING SOLUTIONS products

LEAK, PRESSURE AND BURST TEST STANDS

Related Searches

- Test stand

- Automatic test stand

- Pressure test stand

- Industrial test bench

- PC-controllable test bench

- Valve test stand

- Hydraulic test stand

- Manual test stand

- Test stand for the automotive industry

- Leak test stand

- PLC-controlled test stand

- Pneumatic test stand

- Torque test stand

- Hose test stand

- Test stand for the aeronautical industry

- Precision test stand

- Force test stand

- Performance test stand

- Flow test stand

- Motor test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.