- Metrology - Laboratory

- Metrology and Test Equipment

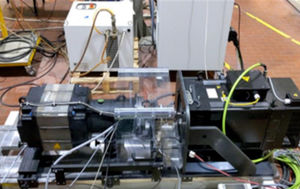

- Force test bench

- BAVA TESTING SOLUTIONS

Force test bench B_23111functionalcomputer-controlledfor actuators

Add to favorites

Compare this product

Characteristics

- Test type

- force, functional

- Operating mode

- computer-controlled

- Test material

- for actuators

Description

B_23111 test bench is designed to complete functional test and force vs time diagram on servo actuated jacks for flight surfaces:

- Proof test: over pressure test of assembly

- Zero flow: hydraulics check of servo valve

- Load functional test

- Jack leakage

- Running in of jack

- Feedback sensor position test

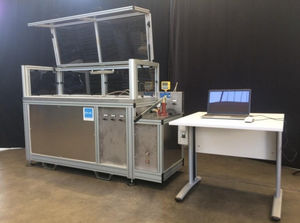

An upper test box, with interlocked doors, can contain the actuator in two position to realize all the tests. Steps of test are completely automated from a software; the control PC

ask periodically an operator confirmation.

The lower box include all the hydraulics equipment and valves and meters to realize test and also the control system for the passive load for functional test.

An external console allows complete control of test bench and can monitor and store all the test data coming from sensors. DAS system is based on NI hardware.

DATI TECNICI:

• OIL: MIL H 5606

• VOLUME: 60 lt

• TEMPERATURE: 35°C [+/-5°C]

• FLOW: 0 ÷ 15 lpm

• OIL SUPPLY LINE: 2

• WORKING PRESSURE: 300 bar

• PROOF PRESSURE: 425 bar

INSTRUMENTATION:

• FLOWMETER 0,03 ÷ 40 lpm

• TEMPERATURE PROBE PT100 (1)

• PRESSURE SENSOR 0 ÷ 45 MPa [+/-0,04

• LOAD CELL 0 ÷ 500 Kg

SAFETY DEVICES:

• Interlocked doors

• Emergency button and safety modules

• Safety pressure switch

• Safety thermostat switch

POWER SUPPLY:

• Electric: 15 kW 400V 3F+N+PE

• Air //

• Water 3,5 bar / 1/2”

DIMENSIONS AND WEIGHT:

• L, p, h: 2000 x 1100 x 2000 mm;

• Raw weight: ~ 800 kg

COLOUR:

• Standard Gray RAL 7035.

NOTE:

• as customer request;

Catalogs

No catalogs are available for this product.

See all of BAVA TESTING SOLUTIONS‘s catalogsOther BAVA TESTING SOLUTIONS products

LEAK, PRESSURE AND BURST TEST STANDS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.