- Metrology - Laboratory

- Metrology and Test Equipment

- Leak test bench

- BAVA TESTING SOLUTIONS

Leak test stand B_22384computer-controlledgearboxfor the aeronautical industry

Add to favorites

Compare this product

Characteristics

- Test type

- leak

- Operating mode

- computer-controlled

- Test material

- gearbox

- Sector

- for the aeronautical industry

Description

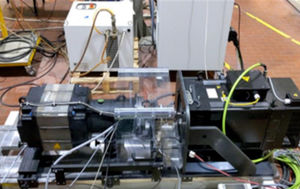

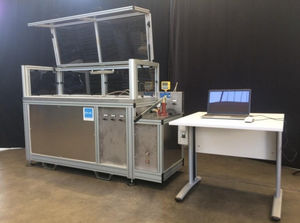

B_22384 is designed to test aeronautical gearboxes with different dimensions and power; from accessory gbx to power gbx.

- End assembly test: right assembly test, shaft seal proof test and bearings lubrication flow values.

- Gbx proof: proof of conduits and casing

- Flushing: internal conduit cleaning and bearings lubrication flow values

The gearboxes under test, installed in special trolleys, are putted into a soundproof cabinet that contains the test bench and all the equipment. A power hydraulic module allows to drive the gearboxes at different speed; the lubricating unit allows to thermoregulate and filtrate the oil

and defines flow test condition: pressure, temperature and flow inlet.

The entire test bench include:

- DAS (Data Acquisition system)

- Thermochiller

- Air filtration system

- Soundproof cabinet

- Service bridge crane

DATI TECNICI:

• OIL: MIL L 23699F

• VOLUME: 300 lt

• TEMPERATURE: 20 ÷ 120°C [+/-0,5°C]

• FLOW: 0 ÷ 30 lpm

• OIL SUPPLY LINE: 3

• PRESSURE: 1500kPa

• SPEED 0 ÷ 4000 rpm [+/- 1]

• POWER 8 kW

INSTRUMENTATION:

• FLOW METERS 0,60 ÷ 30 lpm

0,45 ÷ 19 lpm

0,38 ÷ 11 lpm

• TEMPERATURE PROBES thermocouples TcK (11)

• PRESSURE SENSORS -100 / 500kPa [+/-0,04

0-2000kPa [+/-0,04

• PICK UP

SAFETY DEVICES:

• Interlock doors

• Emergency pushbutton

• Safety pressure switch

• Safety thermal switch

POWER SUPPLY:

• Electric: 25 kW 400V 3F+N+PE

• Air 6 bar / ½”

• Water 3,5 bar / 1”-1/2

DIMENSIONS and WEIGHT:

• L, p, h: 3000 x 3000 x 2850 mm;

• Raw load: ~ 4000 kg

COLOUR:

• Standard Gray RAL 7035.

NOTE:

• as customer request;

Catalogs

No catalogs are available for this product.

See all of BAVA TESTING SOLUTIONS‘s catalogsOther BAVA TESTING SOLUTIONS products

LEAK, PRESSURE AND BURST TEST STANDS

Related Searches

- Test stand

- Automatic test stand

- Pressure test stand

- Industrial test bench

- PC-controllable test bench

- Valve test stand

- Hydraulic test stand

- Manual test stand

- Test stand for the automotive industry

- Leak test stand

- PLC-controlled test stand

- Pneumatic test stand

- Torque test stand

- Hose test stand

- Test stand for the aeronautical industry

- Precision test stand

- Force test stand

- Performance test stand

- Flow test stand

- Motor test bench

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.