- Detection - Measurement

- Optical and Acoustic Measurements

- Shock and vibration switch

- BDC ELECTRONIC S.r.l.

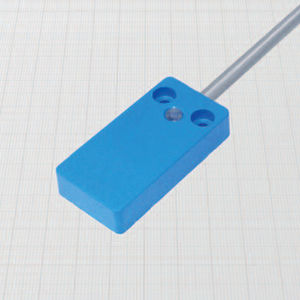

Shock and vibration switch VxS12X series

Add to favorites

Compare this product

Description

3 AXES VIBRATION AND SHOCK SENSOR •

4÷20 mA Output •

M12x1 connector output •

General features:

These new accelerometers give a single 4 ÷ 20 mA signal proportional to the

vibrations applied to X, Y and Z axes. Since the measurement is made from a very

low frequency, the acceleration due to gravity is not detected, so the measurement

will not be affected by the mounting position.

Depending on the connection polarity (direct or reverse) it's possible to perform the

RMS measurement on the vectorial sum of the acceleration on the three axes X, Y

and Z or the instantaneous value , simply reversing the two connection wires.

On the version VBS... (bump sensor) the highest instantaneous value is held on the

output for one second, allowing analogue value measurement.

For a reliable connection it is recommended to use M12x1 connectors with the

shield of the cable connected to the nut (see section H of the catalogue).

Applications:

• Collision detection on electrospindles, handles and robot arms

• Unbalancing detection of tools on milling and grinding machines

• Detection of wearing or abnormal working of ball bearings and rotating parts

• Detection of incorrect loading of drum in washing machines

• Out of balance loads on rotating machinery

Technical data:

• Measuring range: ± 6 g; ± 10 g

• Supply voltage: 8 ÷ 40 Vdc

• Output current : 4 ÷ 20 mA

• Output current variation: see the table

• Hold time of the peak value (version VBS…) 1 sec.

• Max survival shock: 2000 g

• Shock and vibration resistance according to EN60068-2-27 EN60068-2-6

Catalogs

General Catalogue

213 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.