- Production Machines

- Other Manufacturing Equipment

- Direct metallization plating line

- BE Semiconductor Industries N.V.

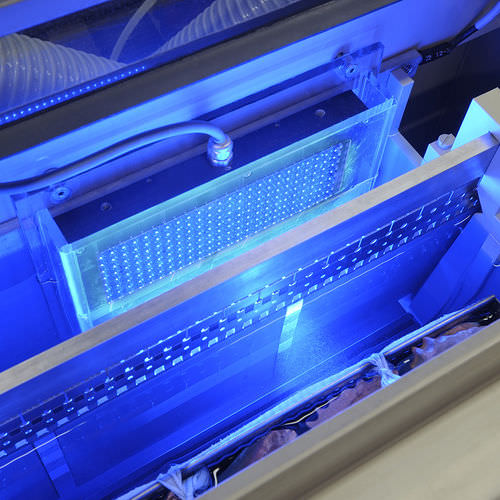

Solar cell plating line Meco DPL direct metallization

Add to favorites

Compare this product

Characteristics

- Options

- for solar cells, direct metallization

Description

For next generation silicon solar cells where the SiNx layer has been opened by laser ablation the Meco Direct Plating Line (DPL) can plate a dense layer of Ni-Ag, Ni-Cu-Ag or Ni-Cu-Sn onto high-ohmic emitters. This results in an efficiency increase up to 1% (abs.) and a tremendous cost reduction (US$/Wp) as no Ag paste is needed anymore for the frontside metallization.

Key Features

•Vertical product handling

•Low drag-out of plating chemicals

•Compact machine design/easy to maintain

•Inline plating process/high up time

•Efficiency improvement : up to 1 % (abs.) with direct metallization

•Bill of Materials (BoM) up to 0.05 US$/Wp lower as no more Ag is needed for frontside metallization

•Proven machine concept (> 350 machines in semiconductor industry)

•Process start-up by Meco

Catalogs

No catalogs are available for this product.

See all of BE Semiconductor Industries N.V.‘s catalogsOther BE Semiconductor Industries N.V. products

Solar Plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.