- Production Machines

- Machine for the electronics industry

- Epoxy die bonder

- BE Semiconductor Industries N.V.

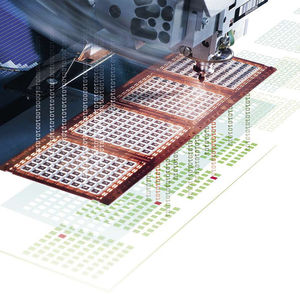

Epoxy die bonder Esec 2100 SC

Add to favorites

Compare this product

Characteristics

- Options

- epoxy

Description

The Die Bonder Esec 2100 SC is the most flexible 300 mm high speed platform, capable of running the smart card tape. It is the most effortless system to run, assist and control production resulting in a quantum leap in throughput and yield at the lowest cost of ownership. At its introduction, this innovative platform was awarded with the prestigious Swiss Technology Award.

Leading Edge Machine Concept

•Single clamp transport system

•100% post bond QC inspection at high speed

•Key alignment tasks performed by cameras make many mechanical adjustments obsolete

•Optional 3 zone heating for pre-curing (accuracy) and void control (dehumidification)

Highest Up Time

•Real time process monitoring through 4 live images of process zones

•Constant status control with real time wafer, tape and magazine viewer

•Efficient learning and error recovery thanks to context sensitive online help

Highest Speed at 25 µm Accuracy

•Phi-Y Pick and Place with symmetrical design for short settling time resulting in highest UPH

•Best placement accuracy through vibration control

•Highest stiffness for highest speed AND accuracy

Fastest Time to Yield

•Tool-less exchange of product and easy loading of material for fastest product changeovers

•Teach and setup wizards and parameter teach verification eliminate setup errors

•Recipe transfer from machine to machine enables fast conversion

The Platform of the Future

•3rd generation pick and place

•50 N bond force standard

•Third process station enables easy adaptation to future leading-edge applications

Catalogs

No catalogs are available for this product.

See all of BE Semiconductor Industries N.V.‘s catalogsOther BE Semiconductor Industries N.V. products

Die Bonding

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.