- Metrology - Laboratory

- Metrology and Test Equipment

- Multi-parameter testing machine

- Beijing United Test Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

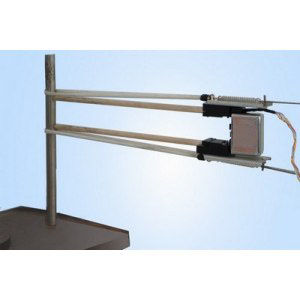

Universal testing machine WDW-300(E / Y)multi-parametercompressionflexure

Add to favorites

Compare this product

Characteristics

- Test type

- universal, multi-parameter, compression, flexure, tension, shearing

- Operating mode

- computer-controlled

- Test material

- for materials

Description

The WDW range of universal testing machines- UTMs- are designed to provide comprehensive solutions for the testing of a wide array of physical characteristics of matter such as bending rates, flexibility, tension, shearing rates and compression. All processes conducted by the electronic machines are guided by computers.

The machines provide excellent results when working with a wide range of metals/non-metals such as steel, steel bars and rods, iron, rebars, etc. Composite matter such as rubber, seat belts, textiles and plastic can be optimally tested for related characteristics. The machines are equipped with the ability to efficiently test properties comprising pneumatic grip, peal, belt tension, tear, punctures, and so on.

The machines are powered by AC servo motors enabling excellent transmission and force moment stability. The clamps used for tension testing processes are equipped with hydraulic wedges to ensure maximized steadiness and ultra-efficiency. The imported ball leading screws provide high levels of exactitude and stability in transmissions.

The extremely resourceful machines are specifically designed for the convenience of manufacturing units, industrial research centers and for the purpose of training students. They are perfectly qualified for use in aeronautics, mechanical engineering, wires and cables production, textiles, construction sector, rubber, appliances and plastic industries. The machines confirm with JIS, ISO, ASTM and BS standards.

Catalogs

No catalogs are available for this product.

See all of Beijing United Test Co., Ltd.‘s catalogsOther Beijing United Test Co., Ltd. products

Universal testing machine

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Digital testing system

- Flexure testing machine

- Tensile test machine

- Industrial testing system

- Laboratory test machine

- Precision test machine

- Rockwell indentation hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.