- Metrology - Laboratory

- Metrology and Test Equipment

- Hydrostatic pressure testing machine

- Beijing United Test Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

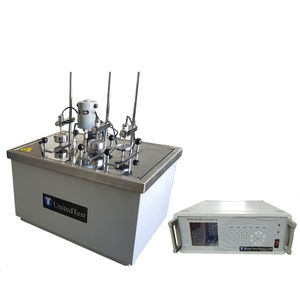

Hydrostatic pressure testing machine HYD seriesforcecomputer-controlledfor materials

Add to favorites

Compare this product

Characteristics

- Test type

- force, hydrostatic pressure

- Operating mode

- computer-controlled

- Test material

- for materials, for pipes

- Sector

- for laboratories, for quality control

- Technology

- hydraulic

Description

HYD series Pipeline hydrostatic pressure testing machine is designed according to ISO 1167, ASTM D1598, ASTM D1599. It’s mainly used to test the plastic pipeline, compound pipeline, such as PP-R, PP-B, PP-A, PVC, PE, PE-X etc. Under a stipulated constant hydrostatic pressure force, keeping provision time; or inside the pipe, apply a constant and rapid hydraulic pressure to make the specimen broken in a short period time, check the max. pressure force, then calculate the ring stress. This tester is necessary equipment for plastic pipe manufacturer.

Feature of HYD-C series:

Computer controlled tester, and touching screen control, pressure 10Mpa (100bar), 20Mpa (200bar), 16mm to 2000mm HDPE,PE,PVC, PPR etc., pipe and pipe fittings.

Principle:

Test pieces are subjected to a specified constant internal hydrostatic pressure for a specified period of time or until a test piece or pieces fail.

Throughout the test, the test pieces are kept in an environment at a specified constant temperature: this is commonly in water (“water-in-water” test).

The following test parameters shall be specified by the standard or specification making reference to this part of ISO 1167:

a) the type of end cap to be used (see 5.1 and ISO 1167-2:2006, 4.1);

b) the test temperature;

c) the number of test pieces;

d) the duration of the test under pressure and the criteria for a failure;

e) the test pressure, p, or the circumferential (hoop) stress, σ, to be induced by the test pressure.

Catalogs

Other Beijing United Test Co., Ltd. products

Plastic & rubber tester

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Compression test machine

- Benchtop indentation hardness tester

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Digital testing system

- Laboratory test machine

- Industrial testing system

- Rockwell indentation hardness tester

- Precision test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.