- Metrology - Laboratory

- Metrology and Test Equipment

- Pendulum impact tester

- Beijing United Test Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

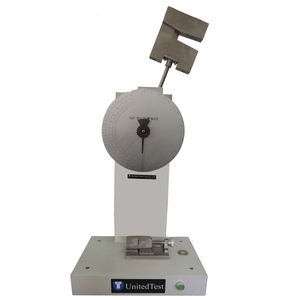

IZOD testing pendulum impact tester XJUD series

Add to favorites

Compare this product

Characteristics

- Applications

- for IZOD testing

Description

Notched Izod Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. Izod specimens are notched to prevent deformation of the specimen upon impact. This test can be used as a quick and easy quality control check to determine if a material meets specific impact properties or to compare materials for general toughness.

United Test product both the IZOD and Charpy impact tester, in dial display, LCD screen display and computer control used determine the impact ductility of nonmetallic materials, such as Rigid thermoplastic and thermosetting plastic, thermosetting plastic and thermoplastic after fiber-reinforced. It is widely used in the industries of plastic products, plastic manufacture, petro chemical etc, University, scientific research institute and commodity inspection department.

Charpy Test: The specimen is mounted horizontally and supported unclamped at both ends. The hammer is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs.

IZOD Test: The specimen is clamped into the pendulum impact test fixture with the notched side facing the striking edge of the pendulum. The pendulum is released and allowed to strike through the specimen. If breakage does not occur, a heavier hammer is used until failure occurs. Since many materials (especially thermoplastics) exhibit lower impact strength at reduced temperatures, it is sometimes appropriate to test materials at temperatures that simulate the intended end use environment.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Beijing United Test Co., Ltd.‘s catalogsOther Beijing United Test Co., Ltd. products

Impact testing machine

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Benchtop indentation hardness tester

- Compression test machine

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Digital testing system

- Flexure testing machine

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Rockwell indentation hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.