- Metrology - Laboratory

- Metrology and Test Equipment

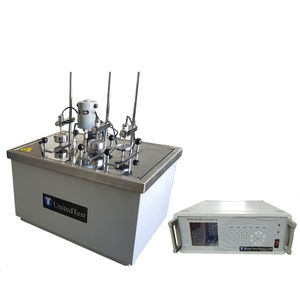

- Stiffness tester

- Beijing United Test Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Stiffness tester RSTcreepthermoplastic pipe

Add to favorites

Compare this product

Characteristics

- Test type

- stiffness, creep

- Tested product

- thermoplastic pipe

Description

RST series ring stiffness tester is used to determine the ring stiffness of circular cross-section thermoplastic pipes, according customer’s request, it can also execute compression, ring stiffness, ring softness and creep ratio test. This tester meet the requirement of all kinds of plastic pipes, structured-wall pipes, PVC, HDPE, LDPE, PE corrugated pipes, helically wound pipes etc.,

Conform with Standard ISO 9969, ISO 9967.

Feature of RST-1 series:

Suitable for small size pipe test (less 630mm dia.); computer control, economical type.

Principle of ring stiffness:

The ring stiffness is determined by measuring the force and the deflection while deflecting the pipe at a constant deflection speed.

A cut length of pipe supported horizontally is compressed vertically between two parallel flat platens moved at a constant speed that is dependent upon the diameter of the pipe.

A plot of force versus deflection is generated. The ring stiffness is calculated as a function of the force necessary to produce a 3% diametric deflection of pipe.

Principle of creep ratio:

A cut length of pipe is placed between two parallel flat horizontal plates and a constant compressive force is applied for 1008 h (42 days). The deflection of the pipe is recorded at specified intervals so as to prepare a plot of pipe deflection against time. The linearity of the data is analysed and the creep ratio is calculated as the ratio between the two years’ extrapolated deflection value and the measured 6 min (0.1 h) deflection.

Other name:

Pipe ring stiffness tester, PVC pipe ring stiffness test, HDPE pipe ring stiffness testing equipment, PE pipe creep rate test, thermoplastic pipe creep ratio test.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Beijing United Test Co., Ltd.‘s catalogsOther Beijing United Test Co., Ltd. products

Plastic & rubber tester

Related Searches

- Test machine

- Measuring device

- Test cabinet

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Compression test machine

- Benchtop indentation hardness tester

- Digital hardness tester

- Vertical test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Digital testing system

- Laboratory test machine

- Industrial testing system

- Rockwell indentation hardness tester

- Precision test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.