- Machine-tools

- Cutting Tool

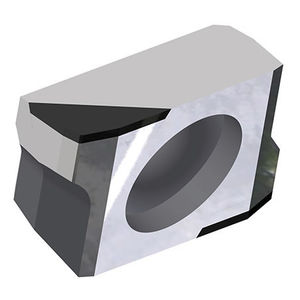

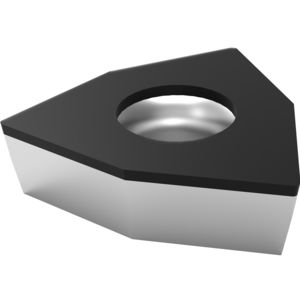

- PCD cutting insert

- Beijing Worldia Diamond Tools Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PCD cutting insert glassstonewood

Add to favorites

Compare this product

Characteristics

- Material

- PCD

- Treated material

- glass, stone, wood, metal

Description

PCD special insert has advantages of high hardness, high compressive strength, good thermal conductivity and good wear resistance, it can get high machining precision and machining efficiency during high speed machining. This PCD tipped insert can be used for processing stone, wood, metal composite materials, glass, engineering ceramics, and so on.

Features of PCD Special Inserts

Main performance index of PCD non-standard insert:

1. The hardness of PCD special insert is up to 8000HV, which is 80 ~ 120 times of hard alloys.

2. The thermal conductivity of PCD is 700W/mK, which is 1.5~9 times of hard alloys, even higher than PCBN and cupper, so the heat can be transferred quickly by PCD tool.

3. The friction coefficient of PCD is only 0.1~0.3 (friction coefficient of hard alloy is 0.4~1), so the PCD tool can reduce the cutting force significantly.

4. The coefficient of thermal expansion of PCD is only 0.9×10 -6~1.18×10 -6, which is equivalent to hard alloy 1/5, so the PCD cutting tool has small thermal deformation and high machining accuracy.

5. The affinity between PCD inserts and non-ferrous metals as well as non-metallic materials is very small, cuttings are not easy to be bonded on the tool tip during the process.

Catalogs

No catalogs are available for this product.

See all of Beijing Worldia Diamond Tools Co., Ltd‘s catalogsOther Beijing Worldia Diamond Tools Co., Ltd products

PCD Cutting Insert

Related Searches

- Worldia milling cutter

- Worldia solid milling cutter

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Worldia metal milling cutter

- Worldia insert milling cutter

- End mill milling tool

- Coated milling cutter

- Cast iron milling tool

- Worldia cutting insert

- General purpose drill bit

- Cutting milling tool

- Hemispherical milling cutter

- Solid carbide milling tool

- Worldia face milling cutter

- Worldia roughing milling cutter

- Carbide drilling tool

- Shell-end milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.