- Packing - Handling - Logistics

- Conveying

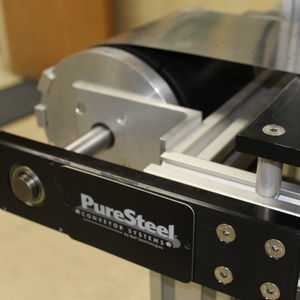

- Flush grid conveyor belt

- Belt Technologies Europe Limited

Perforated conveyor belt vacuumstainless steelsmooth

Add to favorites

Compare this product

Characteristics

- Type

- perforated, vacuum

- Material

- stainless steel

- Pattern

- smooth, toothed

- Sector

- for the packaging industry, medical, for the pharmaceutical industry, for the electronics industry

- Applications

- for the printing industry

- Other characteristics

- custom

- Width

900 mm

(35.43 in)- Thickness

0.1 mm, 0.8 mm

(0.004 in, 0.031 in)

Description

Belt Technologies has the capability to design and produce perforated metal conveyor belts using stainless steel with custom perforation patterns. We can apply the variety of available patterns through specialized perforation methods to guarantee the belt you order is the best match for your application.

Through careful and exact placement of the perforations along the length of the belt, we’re able to ensure the precise and accurate positioning of both the belt and products throughout their production process. Often leveraged by companies requiring precision indexing, perforated belts can be used in vacuum conveying and most any industry or company that is in need of secure transportation for the following applications:

• Solar panel production

• Printing presses

• Packaging

• Clean room environments

• Electronics manufacturing

• Pharmaceutical processing

• Medical device manufacturing

In addition to vacuum suction, perforated belts can be used in a variety of automated systems and automation tasks, including:

• Carriage positioning

• Indexing

• Timing

Perforation Methods and Techniques

A variety of methods can be used to create perforation patterns in PureSteel® stainless steel belts, such as stamping and laser cutting, and chemical etching. Some methods are more damaging to the structural integrity of the metal than others, but these challenges can often be overcome by consulting with our experienced sales engineers to determine optimal perforation patterns and methods in reference to your specific application.

Catalogs

No catalogs are available for this product.

See all of Belt Technologies Europe Limited‘s catalogsOther Belt Technologies Europe Limited products

Stainless Steel Belts

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Belt Technologies conveyor belt

- Conveyor for the food industry

- Plastic conveyor belt

- Electric drive conveyor

- Industrial conveyor belt

- Perforated conveyor belt

- Stainless steel conveyor

- Materials handling conveyor

- Conveyor roller

- Conveyor belt for the food industry

- Conveyor for the pharmaceutical industry

- Food conveyor belt

- Vertical rail conveyor

- Process conveyor belt

- Part conveyor

- Flexible conveyor belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.