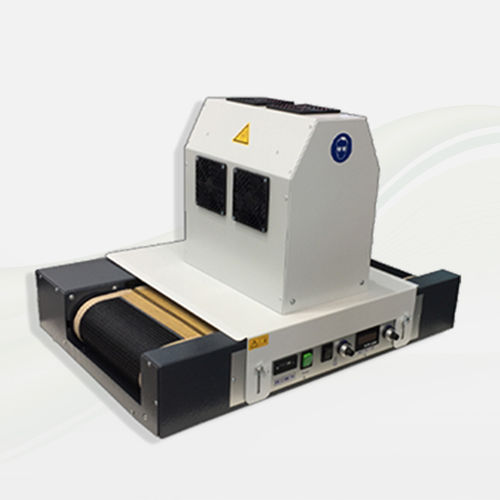

UV LED curing system LED BE 20for coatingfor dryingwith belt conveyor

Add to favorites

Compare this product

Characteristics

- Options

- UV LED

- Autres caractéristiques

- for coating, for drying, with belt conveyor, bench-top

Description

Application:

UV-curing drying inks, printing inks, coatings, adhesives and other UV-sensitive materials by polymerization rather than evaporation of solvents. So far, conventional mercury UV lamps were used for the cure, but meanwhile, the efficient, environmentally friendly UV-LED technology is a proven and superior alternative. Unlike mercury vapor lamps, the LED curing use semiconductor-based LEDs to generate ultraviolet (UV) light. BELTRON relys on the UV-LED technology's advantages with maximized performance, reliability and UV energy.

Design:

The complete turnkey unit is equipped with a UV LED light irradiation unit. Since the heat generated during the

UV-LED radiation is only 1 / 10 of the heat produced during the conventional UV irradiation, the cooling and exhaust

fans consume less and accordingly less energy. The plant is designed for a working width of 15 cm . The lamp can

be started and stopped instantly and therefore no shutter is required during production. The uv power is adjustable

within 20 to 100%.

Catalogs

LED UV dryer BE 20

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.