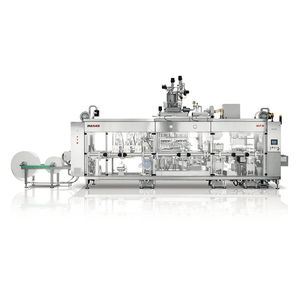

Plastic film form-fill-seal machine C500for dairy product packagingfor cup productionfor food packaging

Add to favorites

Compare this product

Characteristics

- Type

- plastic film

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Other characteristics

- in-line

- Film width

590 mm

(23 in)- Maximum depth of draw

90 mm

(4 in)

Description

The C500 is a medium to high output FFS machine for cups and dual cavity cups, ensuring increased efficiency, accuracy and great flexibility. Handles a wide variety of cup shapes including dual cavity cups. C500 is available in clean design up to full aseptic

Optimum hygienic standards

Able to handle a wide selection of cup shapes and dual cavity cups in all packaging material types, the C500 has a reduced footprint and represents a wise investment thanks to low maintenance needs and negligible spare parts costs.

Key functions are servo-driven to ensure optimum process control and the working width is optimised in line with the requested production capacity.

Nominal output ranges from 10.000 to 57.600 cups/h according to type and size. Available for clean, ultra-clean and aseptic hygienic standards.

1.

Modular design.

2.

Extended shelf life thanks to chemical-free (steam aseptic) aseptic packaging process.

3.

On demand, equipment delivered compliant with further regulations (FDA, 3A and EHEDG etc.).

4.

Enhanced HMI and software.

5.

High availability and low TCO.

6.

In-line cup decoration to suit customer requirements.

Covering a wide range of filling styles, countless tailor-made design possibilities are available to satisfy specific requests. Built to ensure maximum flexibility, different products can be processed on the same machine, also small and large volumes.

Products to be filled

With the Form, fill and seal machine C500 you can fill all kinds of liquid-to-pasty dairy or food products - with or without particulates.

VIDEO

Catalogs

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.