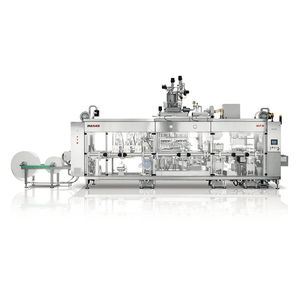

Roll-fed form-fill-seal machine C800for food packagingfor dairy product packagingfor cup production

Add to favorites

Compare this product

Characteristics

- Type

- roll-fed

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Other characteristics

- high-speed

- Film width

800 mm

(31 in)- Maximum depth of draw

90 mm

(4 in)

Description

The C800 is a high-performance FFS machine ensuring optimum hygienic standards, intelligent technological solutions and high cycle speeds to optimise production costs. Able to handle a huge variety of cup shapes, C800 also ensures high filling accuracy.

High filling accuracy. Optimum working width.

Equipped for an endless range of cup designs as well as dual cavity cups in all packaging material types, the C800 ensures top-level productivity, optimised working width in line with the requested production capacity and an excellent cost per cup value.

Able to fit different dosing systems, the C800 processes all kinds of liquid to pasty food products such as single and multi-layer desserts and other special product presentations, as well as baby foods and much more.

Nominal output ranges from 43.200 to 80.640 cups/h according to cup type and size. Available for clean, ultra-clean and aseptic hygienic standards.

C800 Highlights

1.

Ideal choice for maximum output needs (up to >80,640 cups/h).

2.

High availability and low TCO.

3.

Enhanced HMI and software.

4.

On demand, equipment delivered compliant with further regulations (FDA, 3A and EHEDG etc.)

5.

Extended shelf life thanks to chemical-free (steam aseptic) aseptic packaging process.

6.

Inline cup decoration to suit customer requirements.

Complying with the 3 hygienic standards – clean, ultra-clean or aseptic – C-Series FFS solutions provide the tailored answer to contemporary market demands to extend the shelf life of high-quality products outside as well as throughout the cooling chain.

Catalogs

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.