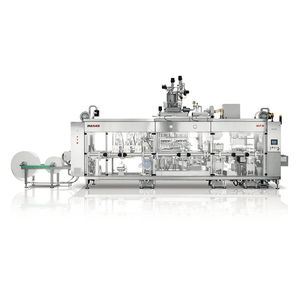

PS form-fill-seal machine EF 400for food packagingfor dairy product packagingfor cup production

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Film width

466 mm

(18 in)- Maximum depth of draw

100 mm

(4 in)

Description

The EF 400 is a high-output FFS machine able to process a huge variety of pasty to liquid products, including multi-layer, and enabling cup design and labelling versatility, leading to significant savings on packaging materials.

Versatility in every sense

The EF 400 provides the most versatile answer to industry needs in terms of cup forming, filling, and sealing, with excellent levels of productivity and potential for tailor-designed cups and filling styles.

Product changeover is quick and easy, and labelling techniques include straight or conical IML as well as in-mould sticker labels.

Cups can be designed cost-effectively with many labelling solutions and freedom of cup geometry. Not only a marketing tool, the label also strengthens the cup’s sidewall stability, enabling a thinner bottom web resulting in lower material costs.

EF400 Highlights

1.

Handles multi-layer PS or PP, PET materials.

2.

Output with or without label: 2 rows of 6 cups of fresh cheese up to 23,000 cups/h.

3.

Output for yoghurt pots: 4 rows of 6 cups up to 46,000 cups/h.

4.

Clean, ultra-clean or aseptic execution, according to specific needs.

5.

FDA, 3A and EHEDG-compliant equipment delivered on demand.

Products to be filled

With the form, fill and seal machine EF 400 you can fill all kind of liquid-to-pasty products - with or without particulates - such as yogurt, fruit juice, white cheese, desserts, pureas, etc.

VIDEO

Catalogs

PACKAGING SOLUTIONS FOR CUPS

24 Pages

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.