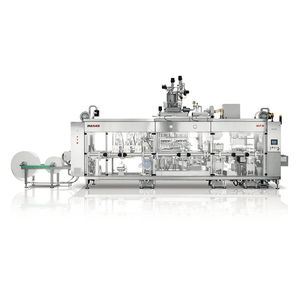

PS form-fill-seal machine C100for dairy product packagingfor cup productionfor food packaging

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Other characteristics

- compact, in-line

- Film width

284 mm

(11 in)- Maximum depth of draw

80 mm

(3 in)

Description

A low output category machine, the C100 handles up to 7,000 cups per hour for all kind of dairy products as well as liquid-to-pasty food products. With a minimal footprint and a modular structure for convenient handling, the C100 is a simple and cost effective solution with only one press.

Thanks to optimised machine design and a simple, intuitive HMI, operational costs, as well as maintenance costs and downtime are kept to a minimum.

1.

Small footprint.

2.

Maximum accuracy, precise product cut-off and gentle product handling.

3.

Servo driven dosing pistons for easy adjustments.

4.

Large variety of cup shapes and designs

Products to be filled

With the form, fill and seal machine C100 you can fill all kind of liquid-to-pasty products - with or without particulates - such as yogurt, fruit juice, white cheese, desserts, pureas, etc.

Filling solutions

With its' long term experience in filling liquid to pasty products into different kind of cups - in thermoformed as well as in pre-formed cups - Erca offers a large variety of different filling possibilities. The fillers are known for their outstanding filling accuracy, a factor which inevitably leads to minimal product loss and enhanced productivity. Covering a wide range of filling styles, countless customized and tailor-made design possibilities are available to satisfy specific requests

Labelling solutions

Cups can be designed cost-effectively and with a huge variety of different labelling solutions. The label is not only a marketing instrument - it also improves the cup’s sidewall stability - making it more rigid so the bottom web thickness for the cup can be reduced.

VIDEO

Catalogs

PACKAGING SOLUTIONS FOR CUPS

24 Pages

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.