PS form-fill-seal machine P300for food packagingfor dairy product packagingfor cup production

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Other characteristics

- compact

- Film width

340 mm

(13 in)- Maximum depth of draw

40 mm

(2 in)

Description

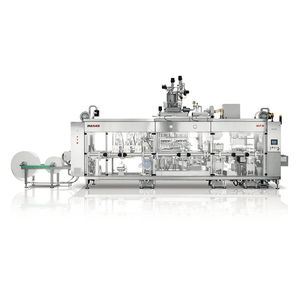

The P300 is a compact and modular form, fill and seal machine for portion cups for multiple food and dairy applications. Offering efficiency at low operational costs, it represents a complete solution when equipped with integrated case packaging systems.

A medium output category machine, the P300 handles between 22.000 and 54.000 portion packs/h. With a minimal footprint, modular structure and reduced web level height for convenient handling, the P300 ensures accurate processing, precise product cut-off and gentle product handling.

Thanks to optimised machine design and a simple, intuitive HMI, operational costs, as well as maintenance costs and downtime are kept to a minimum.

Integrated end-of-line equipment can be fitted to make the P300 a complete solution for efficient packaging and superb productivity. Available for clean, ultra-clean and aseptic (FDA) hygienic standards.

1.

Small footprint.

2.

Low web level height for improved ergonomics.

3.

Automatic, fully controlled SIP/CIP systems for maximum hygiene; equipment supplied in full compliance with European regulations.

4.

On demand, equipment delivered compliant with further regulations (FDA, 3A and EHEDG etc.).

5.

Extended shelf life thanks to chemical-free (steam aseptic) aseptic packaging process.

6.

High availability and low TCO.

7.

Integrated end-of-line equipment makes it a complete solution.

Products to be filled in portion cups

The convenient portion cups can be used to fill butter, desserts, cream cheese, soft cheese, ketchup, mustard, mayonnaise, sauces, jams, honey, spreads, dressings, etc.

VIDEO

Catalogs

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.