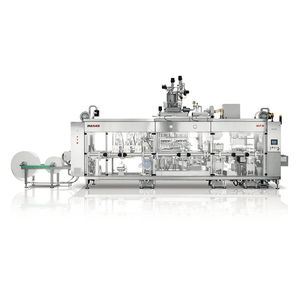

PS form-fill-seal machine P500for food packagingfor dairy product packagingfor cup production

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for dairy product packaging, for cup production, for food packaging

- Operational mode

- automatic

- Film width

590 mm

(23 in)- Maximum depth of draw

40 mm

(2 in)

Description

Ensuring a nominal output of up to 108.000 portion cups/h, the P500 represents the ultimate FFS solution, also integrating case packaging for maximum efficiency.

Ideal for hygienic mini-portions of jam, honey, spreads and sauces used on airlines, at hotels or for simple catering purposes, the P500 is available for clean, ultra-clean and aseptic hygienic standards, and ensures accuracy, precise product cut-off and gentle product handling.

Able to handle a large variety of materials such as PS, PET and PP, one of the key characteristics of this high output machine is the significant saving on packaging material, made possible thanks to a series of exclusive features.

1.

High-performance equipment for clean, ultra-clean and aseptic (steam aseptic) hygienic standards.

2.

Low-waste punch unit for minimal punch waste and reduced material consumption.

3.

Evenly calibrated heating of forming material for optimum wall thickness.

4.

Optimised packaging configurations for volume savings.

Products to be filled in portion cups

The convenient portion cups can be used to fill butter, desserts, cream cheese, soft cheese, ketchup, mustard, mayonnaise, sauces, jams, honey, spreads, dressings, etc.

VIDEO

Catalogs

Related Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.