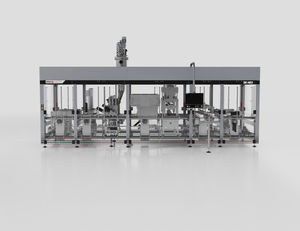

Automatic filling and sealing machine Dogasepticcupliquidsfor dairy products

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Container type

- cup

- Fill product

- liquids, for dairy products, for pasty products

- Product applications

- for the food industry, for pasty products

Description

With a completely enclosed processing tunnel with sterile air overpressure, the DOGASEPTIC filling and sealing machine is the ultimate answer for ultra-clean and aseptic processing thanks to packaging material sterilisation and safe germ reduction.

Completely enclosed machine, with sterile air overpressure.

Providing the safest levels of hygiene with germ reduction up to log 6 bacillus subtilis, the DOGASEPTIC filling and sealing machine for pre-formed cups completes the process thanks to a conveyor inside an enclosed tunnel with sterile air overpressure. The DOGASEPTIC is ideal for fermented milk products, desserts, aerated products, cream, fruit preparations/sauces, soft drinks, etc. Maximum filling volume reaches 550 ml and output ranges between 9,600 and 20,160 cups/h.

1.

Completely enclosed machine.

2.

Conveyor in an enclosed tunnel with sterile air overpressure.

3.

Ultra-clean or aseptic execution, according to specific needs.

4.

Divided product hopper for assorted filling as an option.

Products to be filled

The DOGASEPTIC was designed for multi-layer and assorted filling of liquid to pasty products - with or without particulates - as well as all types of yoghurt and desserts such as custard, pudding and mousse - with and without cream toppings.

Filling Solutions

With its' long term experience in filling liquid to pasty products into different kind of cups GASTI offers a large variety of different filling possibilities. The fillers are known for their outstanding filling accuracy, a factor which inevitably leads to minimal product loss and enhanced productivity.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Benhill GmbH‘s catalogsRelated Searches

- Filling and sealing machine

- Automatic filling and sealing machine

- Liquids filling and sealing machine

- Filling and sealing machine for the food industry

- Cup filling and sealing machine

- Pasty product filling and sealing machine

- Automatic form-fill-seal machine

- Form-fill-seal machine

- Liquid filling and sealing machine

- Packaging form-fill-seal machine

- Cheese filling and sealing machine

- Cup production form-fill-seal machine

- Sauce filling and sealing machine

- Roll-fed form-fill-seal machine

- Compact form-fill-seal machine

- Water filling and sealing machine

- PS form-fill-seal machine

- Margarine filling and sealing machine

- Plastic film form-fill-seal machine

- Coffee filling and sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.